Spark spectrometry: Truly destructive—or just a preconception?

Spark spectrometry has been an established method for the chemical analysis of metallic materials for decades. It enables fast and precise determination of the elemental composition and is used in quality assurance, process control, and incoming goods inspections, among other things. In the metalworking industry, it is considered a reliable tool for ensuring that materials exactly meet the required specifications.

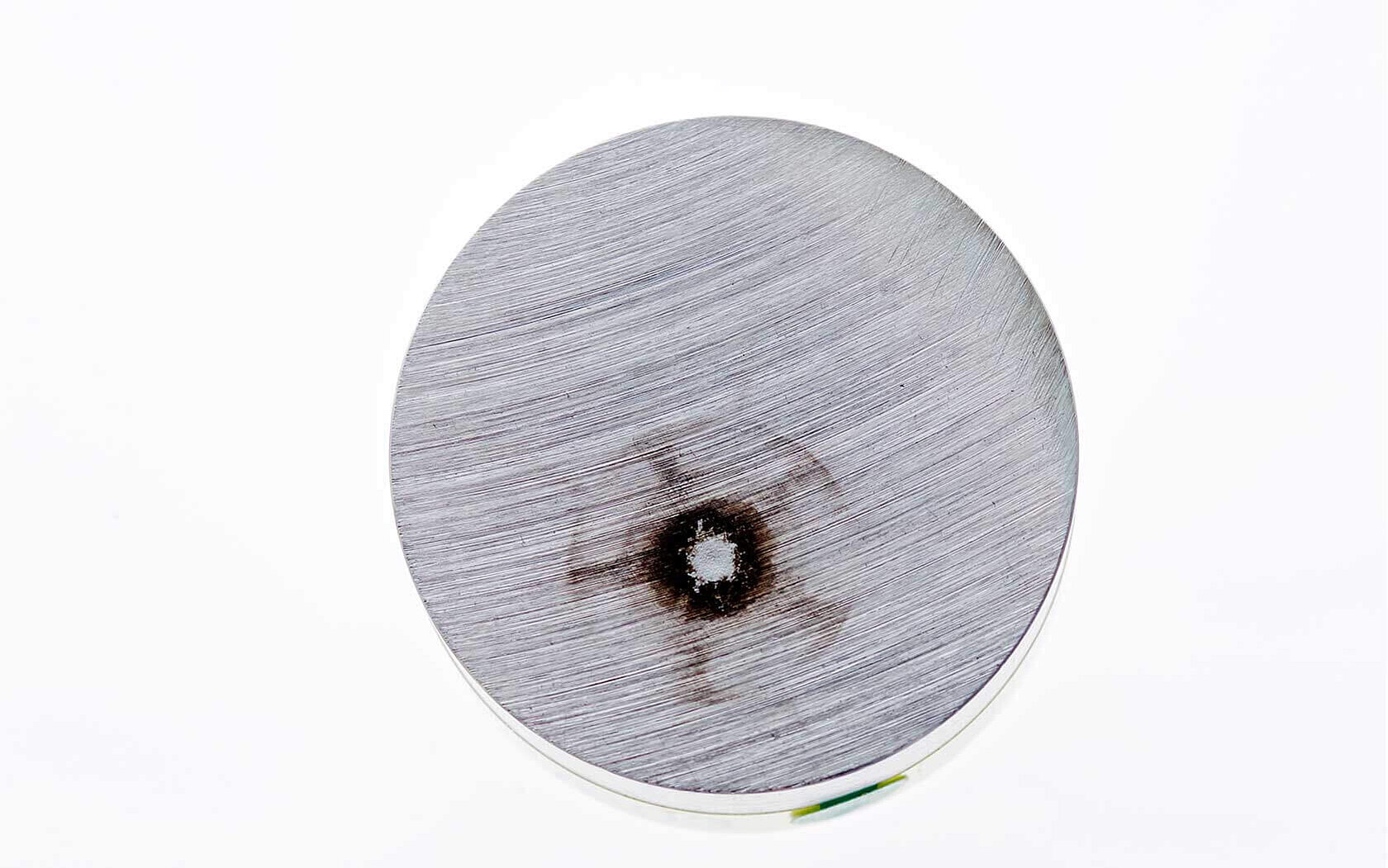

Despite these advantages, spark spectrometry still has a critical reputation today. The reason for this is the burn mark that appears on the metal surface during analysis. Since this is visible to the naked eye, the method is often classified as “destructive” without questioning whether and to what extent the material properties are actually affected.

This is precisely where a differentiated approach comes in, developed in collaboration with the Technische Hochschule Mittelhessen (THM) University of Applied Sciences. Even if the burn mark visually alters the workpiece, the crucial question remains: Does this local impact have a negative effect on the material properties? Or are the functionality, microstructure, and material resistance of the workpiece preserved?

In the following, we take a closer look at the burn mark and evaluate if visible traces are automatically synonymous with relevant material damage, to answer the question if spark spectrometry can be considered a destructive technique or not. The results of our investigations can also be found in our Technical Note: “Burn mark without consequences?".

What really happens at the burn mark

In spark spectrometry, the chemical composition of a metal is determined by a brief spark discharge. This creates a plasma through which element-specific radiation from the material being examined is emitted—the basis for precise material analysis. The plasma only affects the material for a short time. The resulting burn spot is very small and only affects a limited area.

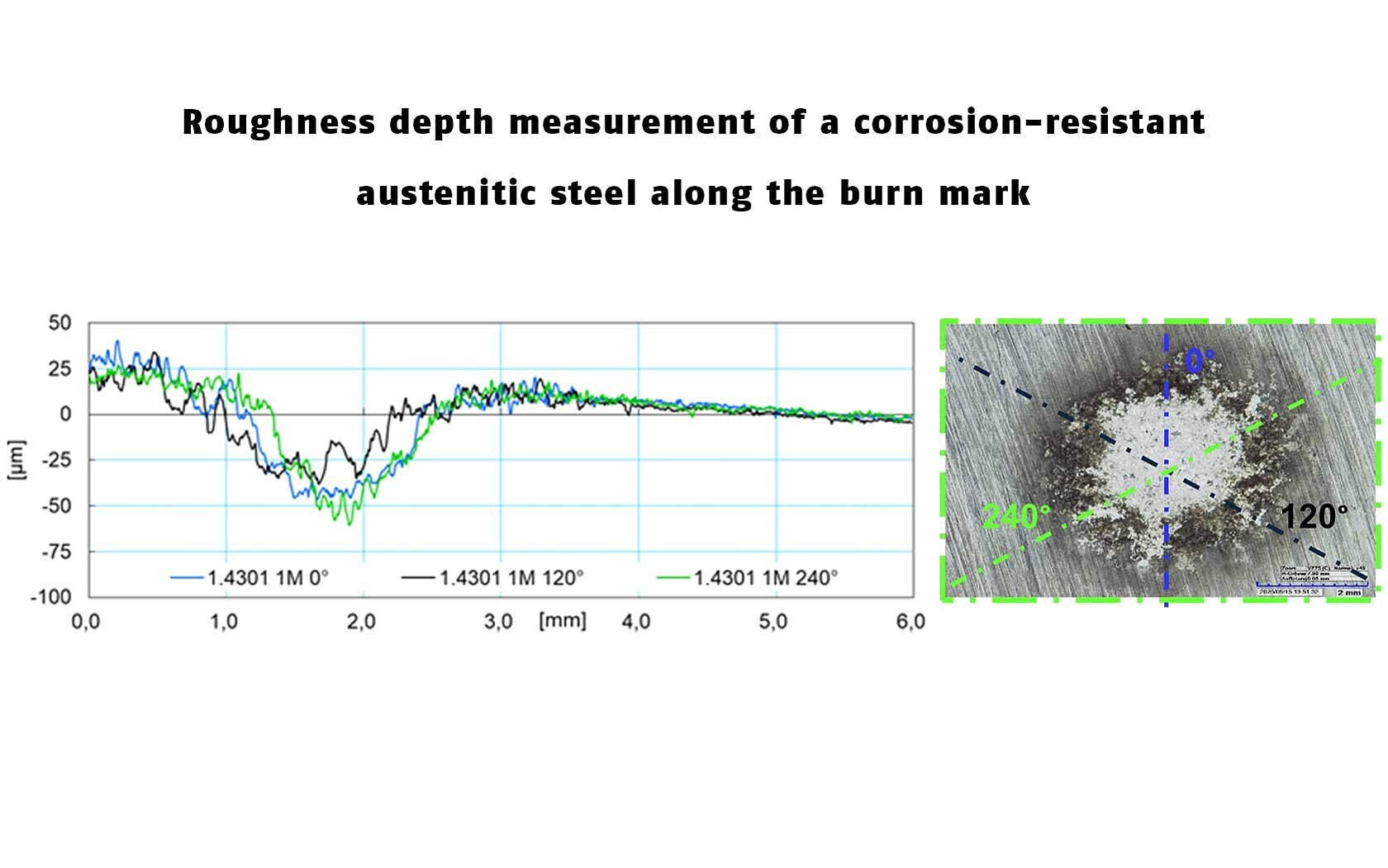

Evaluations show that the depth of the burn spot ranges between 45 and 75 micrometers, depending on the material. For comparison: Many common manufacturing processes such as welding, cutting, or milling affect materials much more strongly – often over several millimeters.

No change in microstructure, hardness, or corrosion resistance

A key finding of the investigations: The burn mark has no measurable influence on the material properties. The results of the investigations in collaboration with the THM refute the widespread assumption that spark spectrometry has a negative impact on material properties.

Microstructure

The remelting caused by the spark is very limited to the local area. Deeper areas of the material remain completely unaffected.

Material hardness

Measurements at different positions show no significant changes in hardness. Differences can be attributed exclusively to the natural microstructural homogeneity of the material – not to the creation of the burn mark.

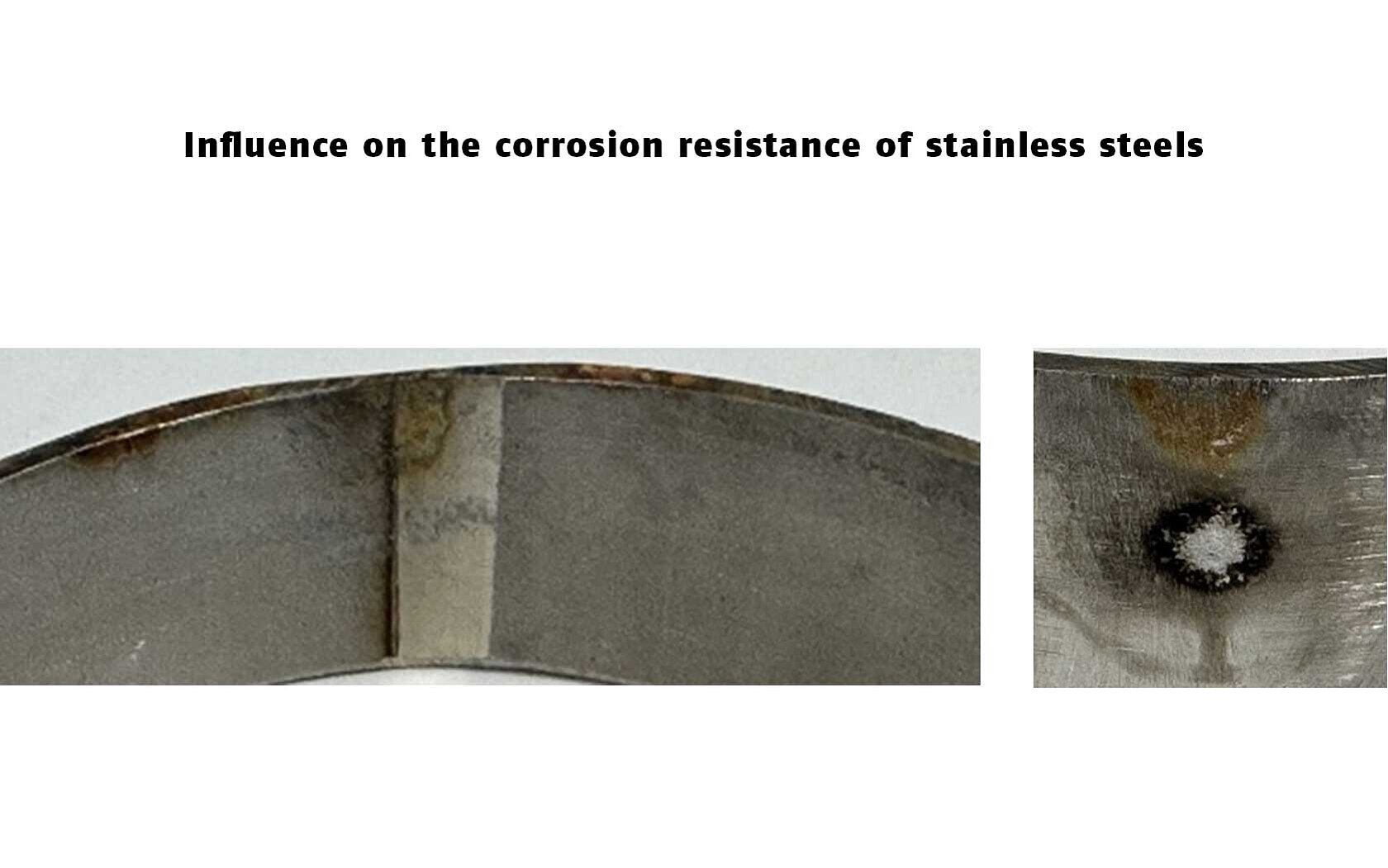

Corrosion resistance

Particularly relevant for many materials: the corrosion resistance of stainless steels is not impaired by the burn mark. Even under extreme conditions, no corrosion occurs at the burn mark – in clear contrast to zones strongly affected by heat, such as weld seams or cut edges.

Why spark spectrometry can be classified as non-destructive

Non-destructive does not mean that no trace is visible – but that

- the functionality of the component is retained,

- the material properties remain unchanged,

- and the material can still be used.

This is exactly what applies to spark spectrometry. Compared to classic destructive testing methods, the impact on the material is minimal – and significantly less than in many everyday processing steps in the metalworking industry.

Thanks to the low impact on the material, spark spectrometry is ideal for:

- Process control in metalworking

- Quality assurance in series production

- Incoming goods inspections

- The analysis of a wide variety of materials – from low-alloy to high-alloy steels

Components do not have to be sorted out or reworked. The analysis can be carried out on the go, directly on the material – quickly, precisely, and with virtually no damage.

Conclusion: A visible burn mark is not damage

Spark spectrometry suffers from a persistent image problem. The visible burn mark is often equated with significant material damage—an impression that is not confirmed by the facts.

The evaluations clearly show:

- The burn mark has no effect on material properties such as structure, hardness, or corrosion resistance.

- This makes spark spectrometry a low-destruction testing method that is ideal for modern metal analysis, process control, and quality control.

- Anyone who wants to analyze materials reliably without damaging them should reevaluate spark spectrometry – and discover the advantages of a modern, mobile spark spectrometer such as ferro.lyte®.

Burn mark without consequences? Optical emission spectrometry with spark excitation in material testing

Please refer to our Technical Note for detailed results of our investigations, conducted in collaboration with the Technische Hochschule Mittelhessen (THM), on the influence of the burn mark on material properties.

DOWNLOAD YOUR COPY

Fill in the form to receive your download link per e-mail.

Your contractual consideration for the free provision of the download is the subscription to our personalized newsletter. By clicking on the “download now” button, you therefore declare your acceptance of the receipt of personalized newsletters by e-mail by Elementar Americas, Inc. and its group companies as well as the evaluation of your user behavior in this regard and - if available - the merging of this data with your data in our customer database.

In order to receive newsletters from our group companies it is necessary to transfer your above-mentioned personal data to these companies. The data transfer is contractually required.

You are aware that the subscription to our personalized newsletter represents the contractual consideration that you provide for the free provision of the download. You can unsubscribe from the newsletter at any time with effect for the future. You can object to the future use of your data for advertising purposes at any time. For further information, please refer to our privacy policy.

Do not miss any new articles

NEWSLETTER

We will constantly publish new blog articles. Register for our newsletter to stay up-to-date and get informed about latest blog articles, news and trends.