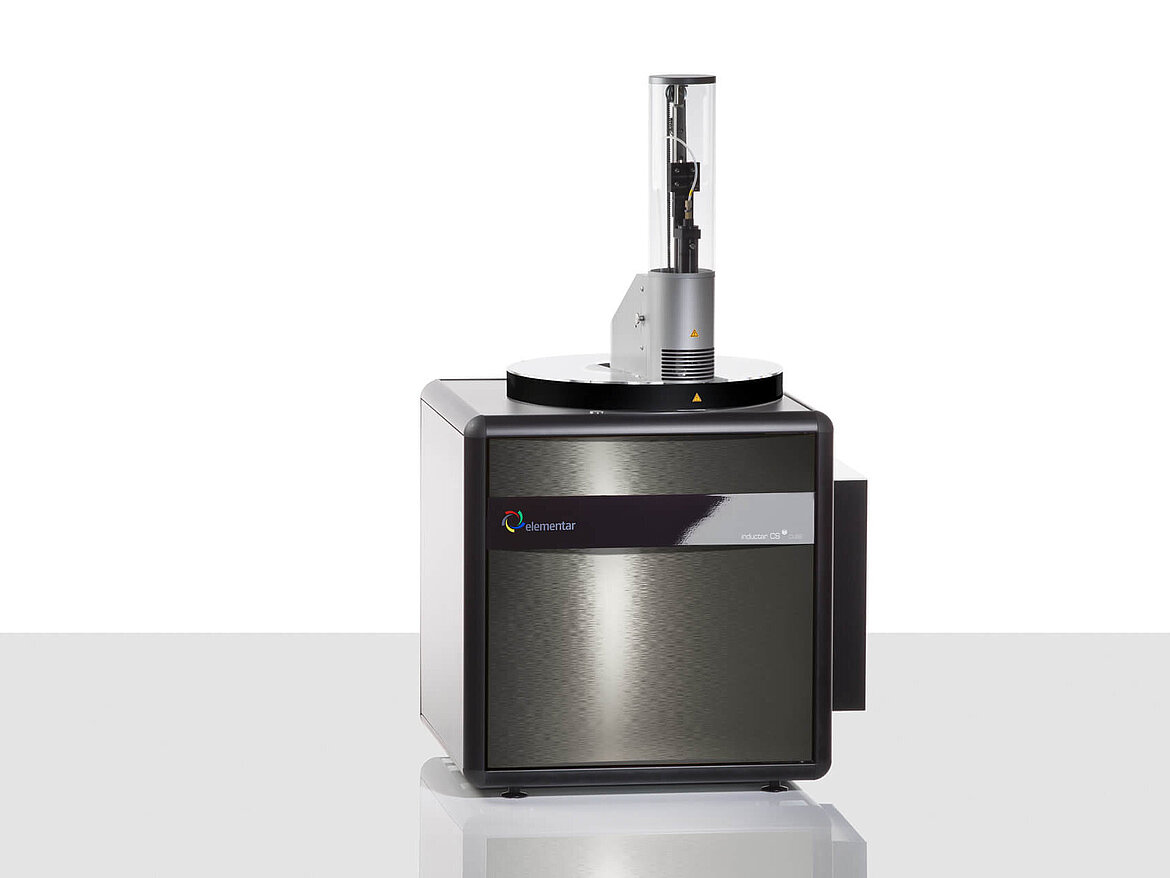

Analyze five elements in only one instrument

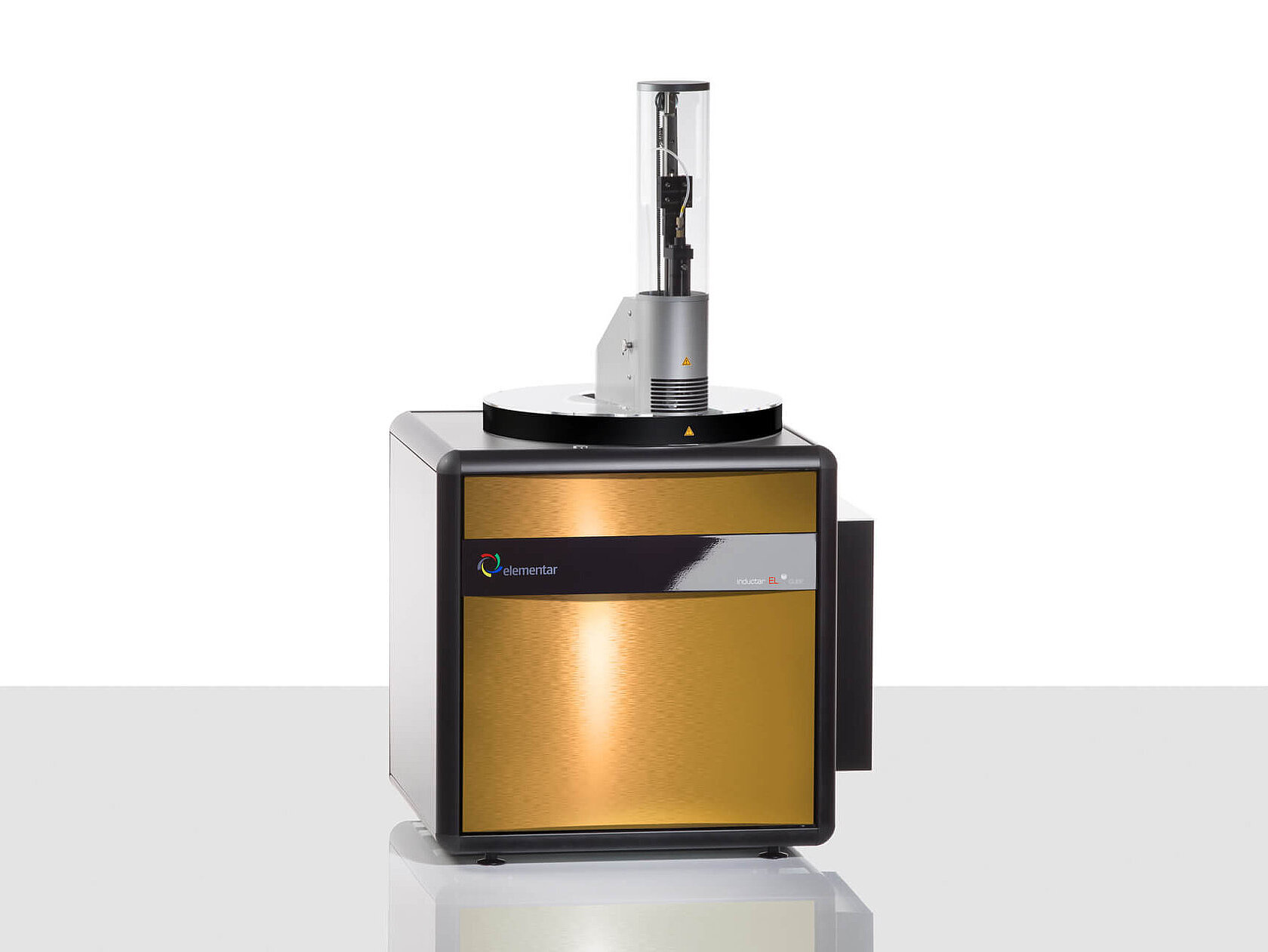

For the very first time it is possible to analyze the concentrations of carbon, sulfur, oxygen, nitrogen and hydrogen in metals and inorganic materials with only one analyzer. The unique inductar® EL cube is a completely new developed analyzer for highly precise and flexible determination of CS and ONH. It is equipped with a long-life solid-state high-frequency induction furnace, which makes it possible to reach sample temperatures of up to nearly 3,000 °C. Furthermore, the innovative technology makes tedious cleaning of oscillator tube and electrodes needless.

Highlights of the inductar EL cube

All-in-one solution for CS/ONH analysis reduces investment costs

and saves laboratory bench space while combining the best out of a CS and an ONH analyzer

Precise results without tedious cleaning

due to our innovative solid-state induction furnace technology

Outstanding instrument flexibility

to fulfill your analytical needs due to the customizable instrument concept that offers different modes, sample feeding options and detection options

Easy handling & low maintenance

because of the intuitive software and the user-friendly instrument concept for daily routine operation

Features

All-in-one solution for CS/ONH analysis reduces investment costs

For the very first time it is possible to analyze the concentrations of CS/ONH in inorganic materials such as metals or ceramics with only one analyzer. Based on our experience of more than 110 years in development and manufacturing of elemental analyzers, this innovative high-temperature CS/ONH analyzer was designed. The inductar EL cube is equipped with a solid-state induction furnace for both CS and ONH analysis, which makes it possible to analyze all five elements with a single analyzer. Investing in one innovative solution instead of two separate instruments saves costs and reduces the needed laboratory bench space massively. The inductar EL cube is best suited for research laboratories and universities or as a backup instrument for the inductar® CS cube and inductar® ONH cube standalone instruments.

Precise results & reduced maintenance without tedious cleaning

The innovative solid-state induction furnace brings the inductar EL cube to the next level. For the first time, it is technologically possible to use induction heating also for ONH analysis. By using smart instrument design and modern induction technology, the required temperatures of nearly up to 3,000 °C can be reached directly at the sample. Solid-state induction heating is in many respects advantageous for inorganic elemental analysis. The first advantage is obviously that no oscillator tube (CS) and electrodes (ONH) need to be frequently exchanged or cleaned, which results in less maintenance and more reliable results. Furthermore, the power and therewith the temperature can be smoothly controlled, which ensures best data quality.

Outstanding instrument flexibility

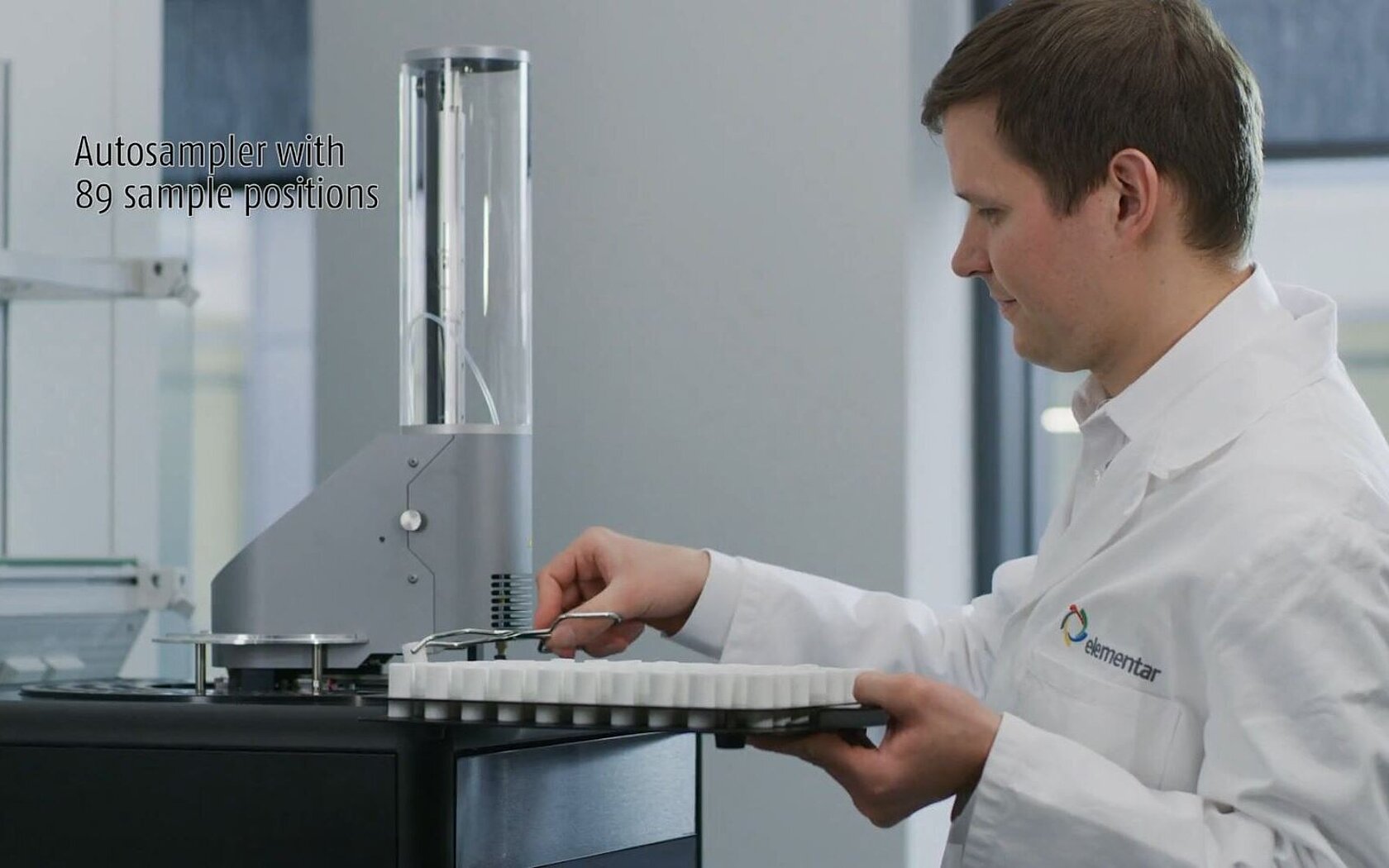

The customizable instrument concept of the inductar EL cube offers a wide range of customization options, suitable for your applicational needs. It combines all the advantages, both analytical and functional, of the stand-alone instruments inductar CS cube and inductar ONH cube in one single instrument. Furthermore, it offers different detection options. The new, innovative hydrogen sensor enables fast & simultaneous ONH determination, without having water in the system. The customizable concept is completed with different sample feeding options including manual samplers and a fully automated autosampler with up to 89 positions. The switch between the two modes CS and ONH is very easy and can be completed quickly by experienced users.

Easy handling & low maintenance

The inductar EL cube is developed for unsurpassed user convenience and maximum robustness. The proprietary solid-state technology for the induction furnace ensures a virtually unlimited lifetime of components. Clearly arranged, easily accessible system components enable you to perform the few needed maintenance within seconds. The tool-free clamp connection system ensures a reliably leak tight instrument at any time. By design, no time-consuming cleaning operations are needed. The lifetime of used reagents is monitored by automated indicators. The intuitive, user friendly software offers not only the easy control the instrument, it also recognizes and prominently displays when maintenance work is needed. Therefore, the maintenance of the instrument is incredibly easy.

Minimal operational requirements

The inductar EL cube has only very minimal operational requirements: Just 628 mm x 607 mm of your bench space in the laboratory, one standard electrical connection and only one gas supply are needed. The inductar EL cube does not need any compressed air in addition to the carrier gas, as the samplers are controlled and moved completely electronically. The long living solid-state induction furnace is highly energy efficient. It reduces power consumption and only needs minimal cooling. No external heat exchanger or connection to the tap water needed. The complete cooling cycle is built inside of the instrument. This makes it incredibly easy to place the inductar EL cube in your laboratory and saves bench space.

Product details

The inductar EL cube is optimized for the determination of carbon, sulfur, oxygen, nitrogen and hydrogen. To switch between the two modes CS and ONH only some easy conversion steps need to be performed. The following modes are available:

CS mode

The CS mode offers simultaneous CS analysis with two wide-range infrared detectors (IR).

ONH mode

The ONH Mode offers simultaneous ONH determination. Oxygen is determined with a wide-range infrared detector (IR), nitrogen with a thermal conductivity detector (TCD) and hydrogen with our proprietary electronic hydrogen sensor (EHS). Furthermore, it offers the possibility to select from reduced modes to achieve the most flexibility:ON mode

OH mode (H with TCD)

H mode

Analysis method

Depending on the selected functionality, the inorganic sample that is to be analyzed will either be combusted in oxygen at above 2,000°C (CS) or melted in inert gas atmosphere at nearly up to 3,000°C (ONH). Subsequently, the resulting gases are analyzed, and all analysis is conducted according to international standards.

Easy sample preparation and handling

CS mode

All kinds of solid samples are weighed into ceramic sample containers (sample mass up to 1 g). No sample preparation needed. Additional additives might be required, depending on the sample material.

ONH mode

There is no need for special sample preparation, meaning all kinds of solid samples can be analyzed if they fit into the ELCAPS ONH nickel capsules and their height does not exceed the capsule’s height. Samples up to 1 g can be handled. For powder samples it is highly recommended to close the nickel capsules with our inPress tool. For some analyses, further additives may be needed.

Measuring five elements in one device

The inductar EL cube is the first analyzer for inorganic materials that combines CS/ONH analysis in one single device. A simple switch will transform the device from CS to ONH and simple maintenance work will ensure the analyzer runs as reliably and accurately as the respective specialized standalone analyzers.

Linear single/multipoint calibration

You, as the instrument operator, will be guided through the calibration by an intuitive calibration assistant. The transparently calculated calibration is editable and storable. Furthermore, templates can be stored for future calibrations. The calibration is linear and stable for months.

Only few operational requirements

The instrument requires only 628 mm x 607 mm of your laboratory working space and only needs one electrical connection (230 V) and one operating gas for maintenance-free, long-term operation. No external cooling or vacuum cleaner required.

Different sample feeding options

The inductar EL cube offers the choice from an automated sampler with up to 89 sample positions as well as a manual sampler with 2 sample positions for both modes.

Full automation

Automated and unattended operation is possible using the integrated autosampler with up to 89 positions and PC-control through Windows®*. Furthermore, optional 21 CFR Part 11 compliant software is available.

Dimensions

With manual sampler: 607 x 628 x 860 mm (W x D x H)

With autosampler: 607 x 628 x 1045 mm (W x D x H)

*Windows is a registered trademark of Microsoft Corporation, Redmond, USA

Optical camera (CS mode)

The optical camera indulive is available for observation of the combustion process. This camera can only be used in CS mode.

Electronic analytical balance

Balance and elemental analyzer form a system. We offer convenient analytical balances from the leading manufacturers with our instruments. Automatic weight transfer from balance to software is possible.

Nickel capsule press inPress (ONH mode)

To securely and easily close the ELCAPS ONH nickel capsules, particularly for powder samples and magnetic samples, we highly recommend using our nickel capsule press inPress. This secures that no material will be lost during analysis.

Lab furnace (CS mode)

We recommend preheating the ceramic crucibles prior to combustion analysis. Especially when low carbon concentrations should be detected, clean and blank-free crucibles are needed. For this preheating step we offer several lab furnaces from leading manufacturers.

Halogen trap (CS mode)

Halogens from halogen containing samples have a major influence on the quantitative detection of carbon and sulfur. Thus, we optionally offer halogen traps for chlorine (intrap-Cl) and fluorine (intrap-F) for best measuring results.

Downloads