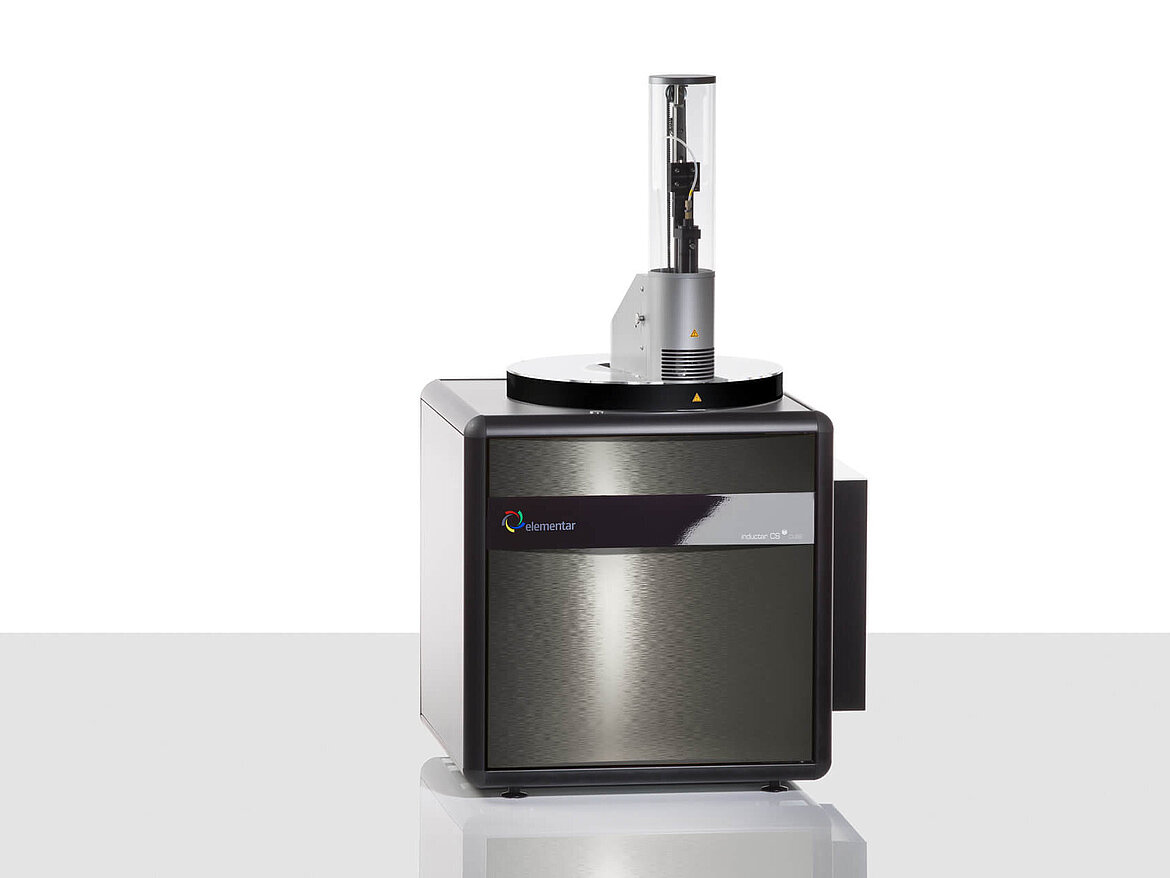

Optical emission spectrometer for precise metal testing. Anywhere. Anytime

ferro.lyte® is a mobile spectrometer, optimized for use in metal production, metal processing and metal recycling. It uses the principle of optical emission spectrometry (OES) with spark excitation. In contrast to conventional handheld instruments, ferro.lyte enables the precise analysis of elements with low atomic numbers such as C, P, S, B, Li, Be, Ca, Si, Mg, Al and the determination of nitrogen in duplex within a few seconds. ferro.lyte convinces with innovative ideas and easy, intuitive handling. The unique design is optimized for flexible, safe and reliable analysis of metal alloys on-site.

Highlights of the ferro.lyte

Flexible metal testing and identification (PMI) on site

with the lightest and most compact optical emission spectrometer of its kind thanks to the innovative all-in-one-concept

Easy, intuitive user interface

for fast navigation through device settings and workflows

Unmatched OES nitrogen analysis in duplex

that was previously only reached by laboratory instruments is possible thanks to the CONLYTE® technology

Simple reporting at the push of a button

via USB, WLAN, LAN or Bluetooth

Time-eater metal analysis? Discover the five key factors for more efficiency.

WHITEPAPER

Learn how ferro.lyte® can help you increase mobility in your metal analysis, maximize safety, simplify processes, improve detection limits, facilitate data management, and thus optimize the efficiency of your on-site quality control.

DOWNLOAD YOUR COPY

Fill in the form to receive your download link per e-mail.

Your contractual consideration for the free provision of the download is the subscription to our personalized newsletter. By clicking on the “download now” button, you therefore declare your acceptance of the receipt of personalized newsletters by e-mail by Elementar Americas, Inc. and its group companies as well as the evaluation of your user behavior in this regard and - if available - the merging of this data with your data in our customer database.

In order to receive newsletters from our group companies it is necessary to transfer your above-mentioned personal data to these companies. The data transfer is contractually required.

You are aware that the subscription to our personalized newsletter represents the contractual consideration that you provide for the free provision of the download. You can unsubscribe from the newsletter at any time with effect for the future. You can object to the future use of your data for advertising purposes at any time. For further information, please refer to our privacy policy.

Features

Flexible metal testing and identification (PMI) on site

ferro.lyte convinces with its revolutionary all-in-one concept, which is designed for maximum user friendliness. The integrated argon bottle holder and a holder for the hand probe make the analyzer easy to transport and safe to operate - even without a trolley. Thanks to the low weight of 16 kg and the compact design, ferro.lyte offers optimal conditions for ad-hoc analysis or positive material identification (PMI) at locations that are difficult to access. It is the lightest and most compact optical emission spectrometer of its kind. In terms of analytical performance, ferro.lyte is as precise as a laboratory instrument.

Easy, intuitive user interface

The intuitive user interface allows quick navigation through instrument settings and workflows. Which software functions are displayed in the main window could be chosen individually. Furthermore, you can choose between the classic analysis display or the alloy ID with target and actual values. Thanks to optical bonding technology, the clear and bright touch screen is easy to read even in the most difficult lighting conditions.

Outstanding nitrogen analysis in duplex

Our innovative CONLYTE® technology significantly improves analytical performance for nitrogen in duplex. In addition, the long-term stability for the measurement of phosphorus, boron and sulfur is increased. In contrast to conventional mobile spectrometers, ferro.lyte uses an extended wavelength range for the determination of the nitrogen content that was previously only reached by laboratory instruments. The extension of the wavelength range is achieved by the unique CONLYTE technology developed from us (filled as a patent). The air gap between the light channel and the plasma, which is common in mobile spectrometers, is completely sealed from the atmosphere. Atmospheric changes therefore cannot influence the measurement signal - a prerequisite for permanently reliable analysis results.

Simple reporting at the push of a button

Analysis results can be exported in a variety of ways: via USB or LAN connection from the analyzer, as well as via WLAN or Bluetooth connection. The powerful cloud technology of the lyticOS® Software Suite optimizes the provision and further processing of measurement results and thus facilitates cooperation with colleagues and business partners. This provides unsurpassed data processing, reporting and traceability for on-site work anytime.

Comfortable cloud service

The analysis results are automatically stored on the optical emission spectrometer and can be uploaded to the secure lyticOS® cloud at the same time. This enables new dynamic working methods. Analysis data can be quickly and efficiently shared and further processed. The measured values are available "on demand" if required at any time for further processing or distribution - even without access to the instrument. This increases security and data availability anytime and anywhere.

Product details

For fast and reliable analysis of low- and high-alloy steels as well as aluminum alloys, non-ferrous metals or special alloys such as titanium, copper and nickel-based alloys, optical emission spectrometers (OES) with spark excitation technique under argon is the method of choice. Within seconds, OES provides the most precise and widest range of analytes of the metallic constituents as well as the non-metals carbon, sulfur, phosphorus and nitrogen.

Specially designed optics

The optics, the heart of every optical emission spectrometer, are specially designed for use in harsh environments. Several sensors, specially developed for ferro.lyte, allow the full wavelength range to be measured without compromising spectral line selection.

Hand probe

The light and ergonomic hand probe is firmly connected to the basic unit with a hybrid cable. The cable is specially designed for use in harsh environments. This protects the optical fiber, minimizes the risk of failure and reduces follow-up costs for costly repairs.

Dimensions

Thanks to its compact dimensions of 425 x 315 x 210 mm, ferro.lyte is the ideal solution for testing areas that are difficult to access.

Weight

With less than 16 kg and its innovative all-in-one concept, ferro.lyte is the first mobile spectrometer that can be carried safely and comfortably.

Electrical connection

ferro.lyte is designed for cordless use. The interaction of the integrated high-performance battery with the intelligent battery management makes ferro.lyte a reliable long-distance runner. For charging the battery, the scope of delivery includes a charger which is designed for a single-phase input voltage with protective ground 100-240 V (+10%/-10%) and one of 50 or 60 Hz.

Transport trolley

Although ferro.lyte is a portable metal analyzer, we still offer a sturdy and ergonomic transport trolley as an additional option. The trolley is the ideal companion for those who have to walk long distances to the measuring point, or rarely have to perform their measuring tasks in hard-to-reach testing areas - such as rod or pipe bearings.

The trolley offers space for the basic instrument as well as other accessories. Even a large argon cylinder with 10 l can be safely stowed away and transported. Large, ball-bearing rollers made of soft solid rubber ensure easy transport on any surface. This makes the transport over long distances even easier and simple - both indoor and outdoor.

Downloads