The lifeblood of our infrastructure: How modern bridge testing ensures safety and durability

Bridges are a vital part of our infrastructure, transporting people and goods safely across rivers, valleys and other obstacles. Steel bridges in particular, known for their high load-bearing capacity and durability, play a central role in rail and road transportation. But even these robust structures are not immune to aging or wear and tear.

Time takes its toll on steel bridges

The average lifespan of a steel bridge is usually between 80 and 120 years, depending on the construction method, load and environmental influences. Day after day, they are exposed to dynamic loads and climatic effects. These factors can significantly impair the load-bearing capacity and operational safety of steel bridges. The most significant loads include:

- Elevated traffic load: Heavy goods traffic is putting more strain on bridges than originally planned (160,000 times more than a car)

- Dynamic loads: Vibrations and oscillations caused by traffic can lead to fatigue cracks in the steel.

- Corrosion: Moisture, road salt and pollutants can attack and weaken the steel.

- Material fatigue: Prolonged repeated stress weakens the microstructure of the material.

- Extreme events: Accidents, floods or earthquakes can cause additional damage.

Bridge monitoring and maintenance: Safety through regularity

According to the German Federal Ministry for Digital and Transport (BMDV), maintenance and modernization are essential elements of safe transport infrastructure. Regular inspections are prescribed by law – for example in DIN 1076, which sets out the following:

- Major inspections every six years

- Basic inspections every three years

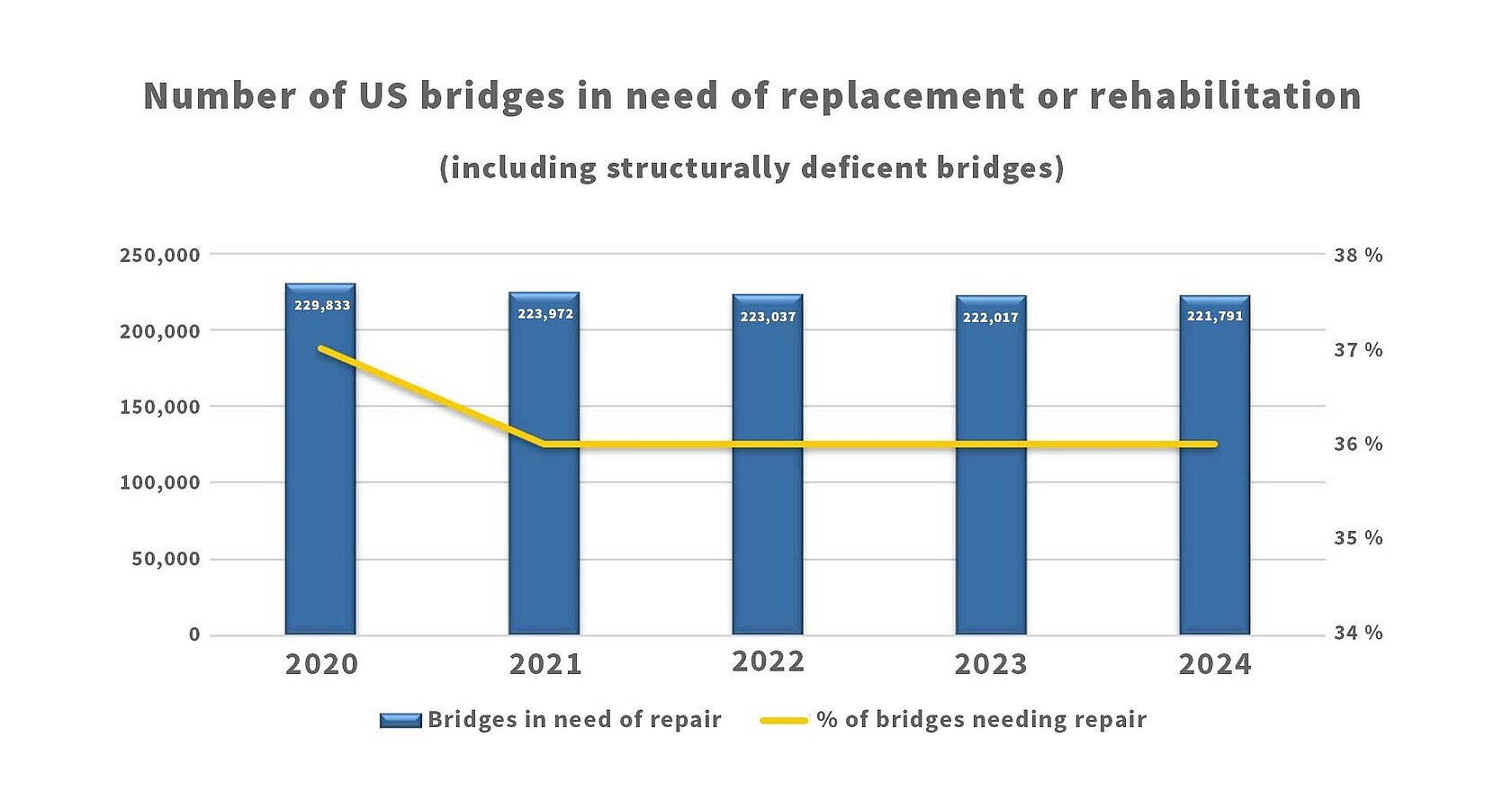

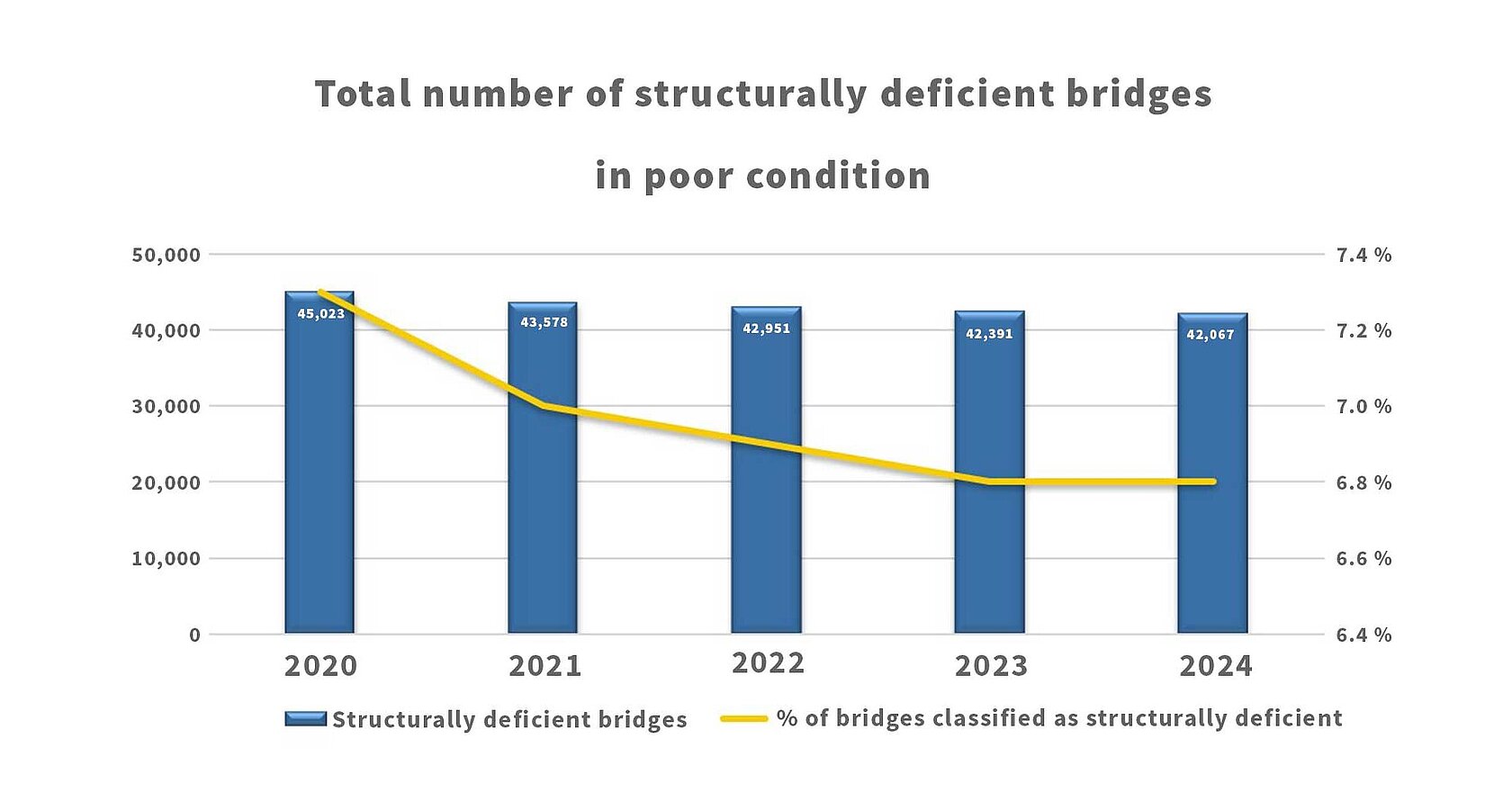

One example among many is the USA’s infrastructure, which is sorely in need of renovation. Many of its bridges are old and ready for an overhaul. According to the American Road & Transportation Builders Association (ARTBA), thousands of bridges are currently classified as structurally deficient, meaning that they require major repairs or need to be completely replaced. Funding bridge rehabilitation is a major challenge: Significant investments are needed to modernize the aging bridge infrastructure and ensure its safety. Infrastructure legislation in recent years, such as the Infrastructure Investment and Jobs Act (IIJA), has earmarked major investments in bridge infrastructure in the USA in an effort to improve this situation.

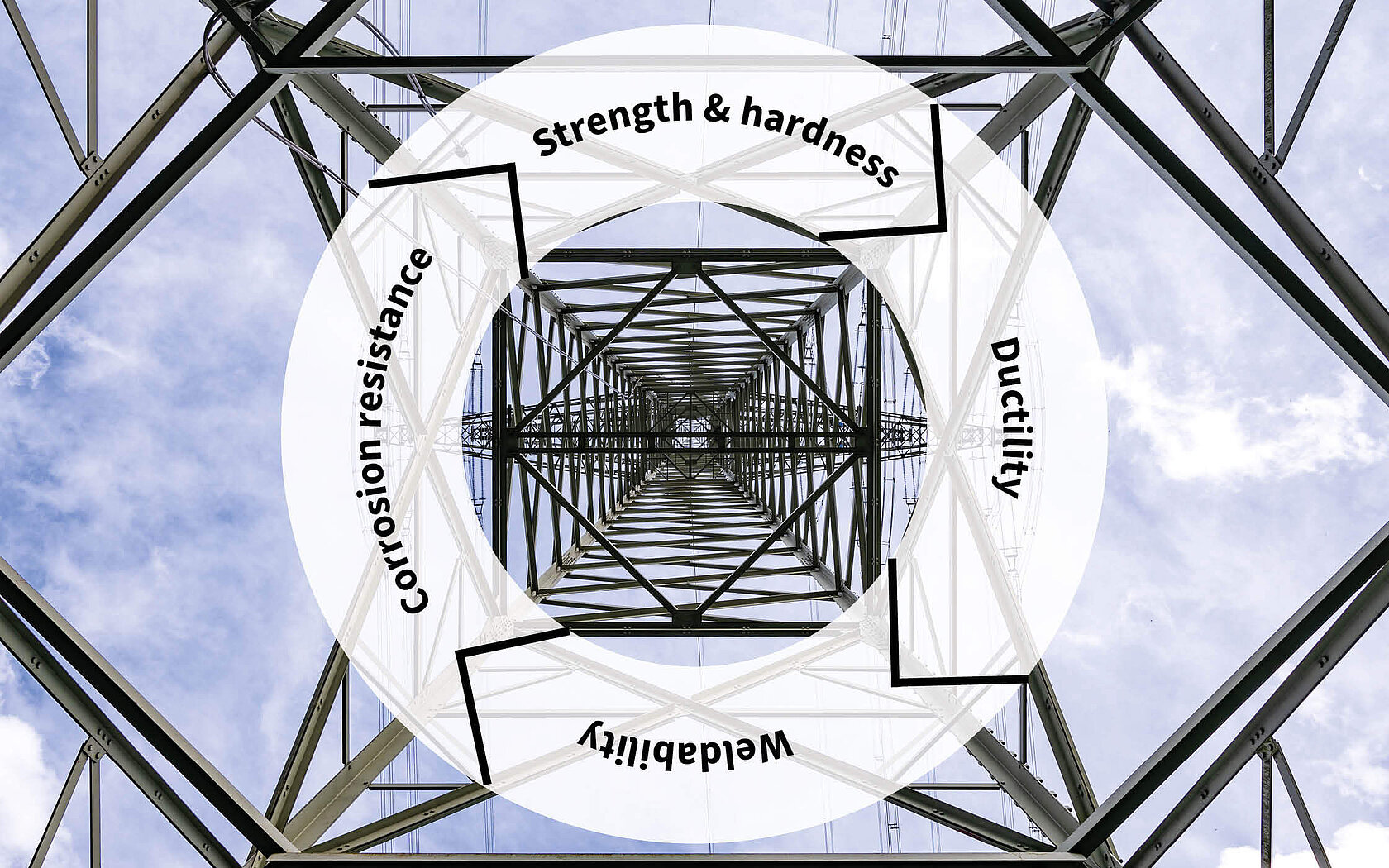

Why the chemical composition of the steel is so important

Not all steel is created equal. Different types of steel have different mechanical and chemical properties, which have a direct impact on corrosion behavior, weldability and load-bearing capacity. For older bridges, there is often a lack of documentation on the materials used. Material analysis is a key element of the overall evaluation here. The equivalent carbon content (CEV) provides information on steels’ suitability for welding – a material with a CEV under 0.45 has good weldability. Interested in more details about the influence of the chemical composition onto material properties? Check out our article The carbon content in steel - a decisive factor for material properties.

Damage-free analysis of bridges with mobile OES

Optical emission spectrometry (OES) is a proven method for analyzing the chemical composition of steels. It can be used to precisely determine the content of carbon (C), silicon (Si), manganese (Mn), phosphorus (P), sulfur (S), nitrogen (N) and other elements. This chemical analysis is the first step in identifying the steel and determining its properties. Mobile OES is especially suitable for this, as it results in only minor destruction and can be conducted on site. This eliminates the need to remove bridge material for laboratory analysis.

The analysis results form the basis for determining which raw materials were used to build the bridge, such as puddle steel or materials based on a newer method. More modern processes such as the Bessemer or Thomas process involve less phosphorus, making the life expectancy of the material longer than that of puddle steel. Although phosphorus is necessary in order to increase the steel’s strength and hardness, an excessive phosphorus content leads to brittleness and makes the bridge more vulnerable to cracking. Once the raw materials used and the suitability for welding have been determined using OES, the next steps can be planned. This is why mobile OES is becoming increasingly important for bridge inspections.

Bridge repairs after appropriate assessment and classification

The bridges are assessed and classified on the basis of numerous aspects such as structural stability, traffic safety or durability. Based on these results, appropriate measures are taken as needed:

- Welding repairs to eliminate cracks

- Reinforcement with additional beams or slabs

- Coatings for corrosion protection

- Replacement of damaged components

The future of bridge maintenance

Digitalization and the use of innovative technologies are set to make bridge maintenance even more effective in the future. Combining precise measurements, modern data analysis and advanced repair techniques helps to guarantee the safety and longevity of bridges, enabling them to continue playing their vital role in our infrastructure. For a real-world example, we can look to the pilot project Smart City Dortmund. In this project, sensors have been installed at five selected bridges in the German city of Dortmund. The sensors measure inclination, strain, cracks and temperature in real time and continuously provide data on the condition of the bridges. The aim is to be able to monitor these bridges continually and enable predictive maintenance. Real-time monitoring thus makes constant risk management possible, which not only increases safety but also optimizes the control of traffic flows. In addition, continuous data analysis allows realistic cost plans to be drawn up for future renovations, which can deliver significant cost savings in the long term.

Conclusion

Bridge testing is more than just a routine technical process – it is crucial to maintaining our infrastructure. With methods such as mobile OES, systematic material analysis, and digital monitoring solutions, we can not only avoid acute hazards, but also effectively extend the service life of our bridges – for greater safety, efficiency and sustainability in the transportation sector.

Interested in bridge testing? Find further information and measurement results in our Application Note "Securing traffic by testing the bridge steel".

DOWNLOAD YOUR COPY

Fill in the form to receive your download link per e-mail.

Your contractual consideration for the free provision of the download is the subscription to our personalized newsletter. By clicking on the “download now” button, you therefore declare your acceptance of the receipt of personalized newsletters by e-mail by Elementar Analysensysteme GmbH and its group companiesas well as the evaluation of your user behavior in this regard and - if available - the merging of this data with your data in our customer database.

In order to receive newsletters from our group companies, it is necessary to transfer your above-mentioned personal data to these companies. We point out that these are partly located in so-called unsafe third countries outside the EU/EEA, in which no adequate level of data protection (e.g. by adequacy decision of the EU, Art. 45 GDPR) is guaranteed. In these countries, you may not be able to enforce your rights as a data subject, or only to a limited extent. In addition, it is possible that local government agencies access your data to a disproportionate extent. The data transfer is based on Art. 49 para. 1 lit. b) GDPR.

You are aware that the subscription to our personalized newsletter represents the contractual consideration that you provide for the free provision of the download. You can unsubscribe from the newsletter at any time with effect for the future. You can object to the future use of your data for advertising purposes at any time. For further information, please refer to our privacy policy.

Do not miss any new articles

NEWSLETTER

We will constantly publish new blog articles. Register for our newsletter to stay up-to-date and get informed about latest blog articles, news and trends.