Elemental analysis in pharmaceutical manufacturing

The pharmaceutical industry places high demands on manufacturers of analytical instrumentation. Highest accuracy, speed, sophisticated automation, unsupervised operation, low maintenance, and absence of downtime are required in this high value product market. Over many decades of production of dedicated analytical instrumentation for the pharmaceutical industry, we have listened to and have learned from our market-leading customers in the pharmaceutical industry. Through patented technologies we have optimized our elemental analyzers for delivering the right results with the highest possible convenience.

GMP Guide: Ready for the audit

In this GMP guide, we collected information for you how to ensure GMP conformity of your analytical processes with qualifications, software and services. Furthermore, it contains application examples in the field of CHNOS analysis of different pharmaceutical samples, peptide content analysis, TOC analysis and cleaning validation as well as ADME studies in the product development phase.

DOWNLOAD YOUR COPY

Fill in the form to receive your download link per e-mail.

Your contractual consideration for the free provision of the download is the subscription to our personalized newsletter. By clicking on the “download now” button, you therefore declare your acceptance of the receipt of personalized newsletters by e-mail by Elementar Analysensysteme GmbH and its group companiesas well as the evaluation of your user behavior in this regard and - if available - the merging of this data with your data in our customer database.

In order to receive newsletters from our group companies, it is necessary to transfer your above-mentioned personal data to these companies. We point out that these are partly located in so-called unsafe third countries outside the EU/EEA, in which no adequate level of data protection (e.g. by adequacy decision of the EU, Art. 45 GDPR) is guaranteed. In these countries, you may not be able to enforce your rights as a data subject, or only to a limited extent. In addition, it is possible that local government agencies access your data to a disproportionate extent. The data transfer is based on Art. 49 para. 1 lit. b) GDPR.

You are aware that the subscription to our personalized newsletter represents the contractual consideration that you provide for the free provision of the download. You can unsubscribe from the newsletter at any time with effect for the future. You can object to the future use of your data for advertising purposes at any time. For further information, please refer to our privacy policy.

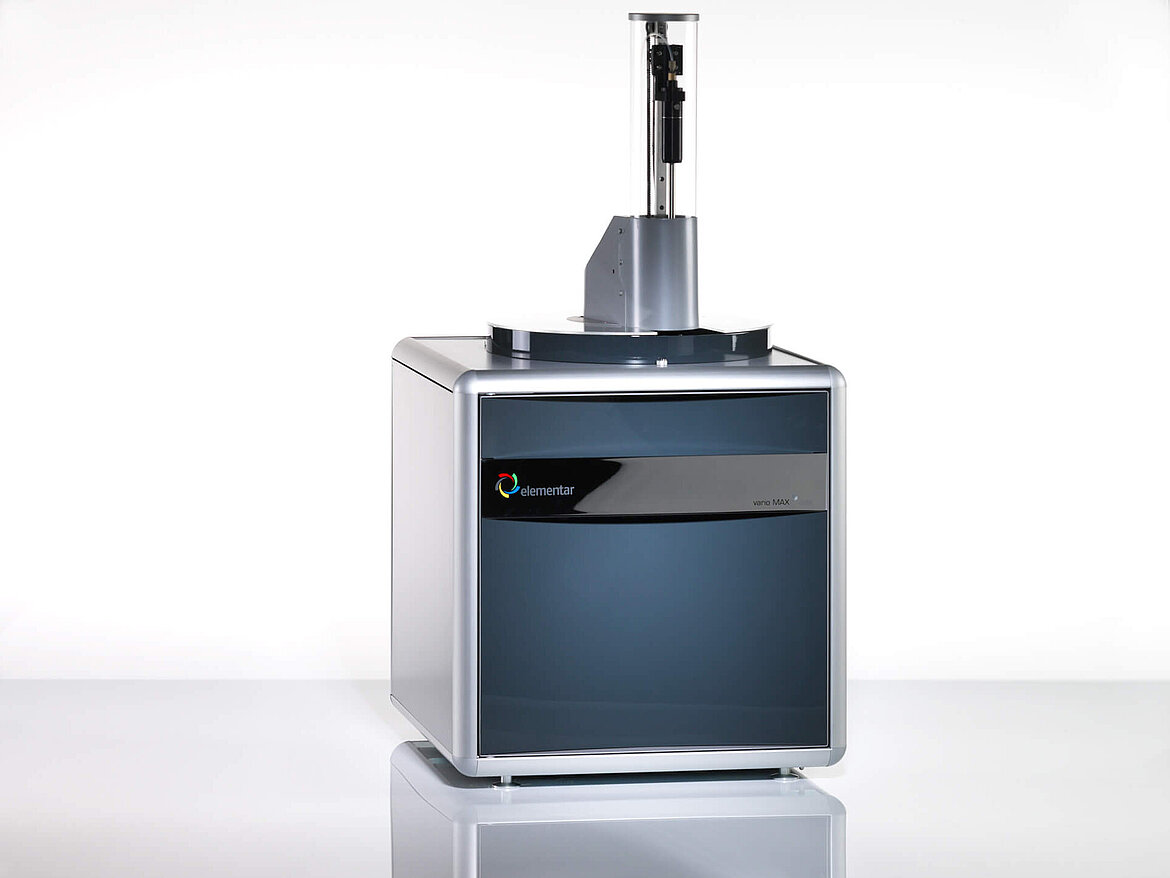

Product quality control of pharmaceuticals

The concentrations of carbon, hydrogen, nitrogen, oxygen, and sulfur in pharmaceutical products often serve as important parameters for quality control of the production process. The concentration of an active substance with a specific elemental composition which is mixed into a carrier material with a different elemental composition can, for example, easily and cost-efficiently be detected by means of elemental analysis.

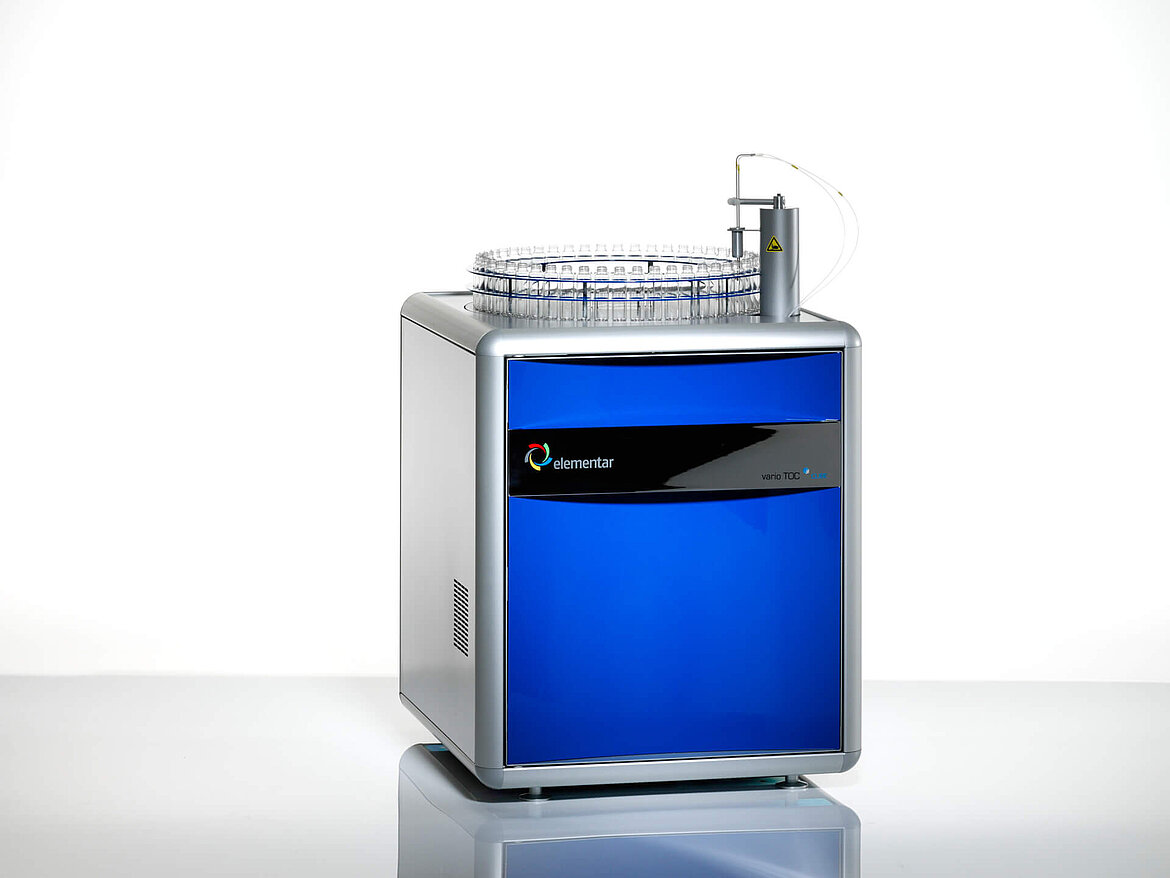

Cleaning validation in pharmaceutical manufacturing processes

To prevent cross-contamination between product batches in pharmaceutical manufacturing processes, the total organic carbon (TOC) analysis method is widely accepted as an industry-wide quality control gold standard. Using this method, manufacturers are able to identify carbon-containing residues in vessels used in manufacturing to confirm they have been cleaned and decontaminated between batches. This is particularly essential for companies developing different products within the same facilities to ensure the production of safe and pure medicines.

Furthermore, TOC analysis is also used to check the water being used in the manufacturing process of pharmaceutical products is of sufficient purity to give high quality products.

Regulated environments in the pharmaceutical industry

To adapt to the special needs which regulatory bodies impose on manufacturers in the pharmaceutical industry, we provide special optional features like uninterruptible power supply, software compliant to 21 CFR part 11, as well as installation qualification (IQ), operational qualification (OQ) and performance qualification (PQ). High system uptime and ease of use are guaranteed through sophisticated self-diagnosis, tool-free maintenance, and full automatization for remote and unattended operation.