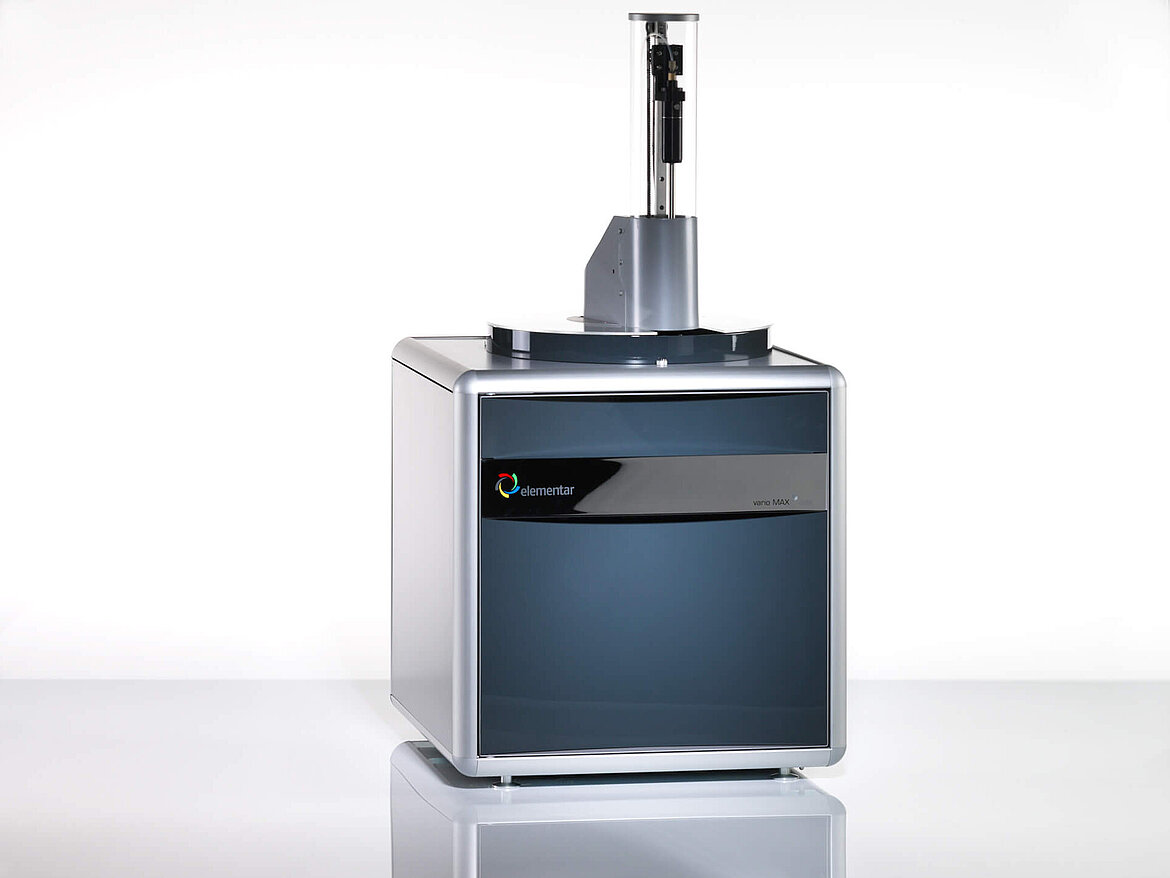

The one and only CHNS macro analyzer

Meet the world’s first macro elemental analyzer for simultaneous carbon, hydrogen, nitrogen, and sulfur determination from one sample: the vario MACRO cube. This universal analyzer for macro sized samples is designed to offer industry-leading versatility in elemental analysis for fullest flexibility in your analyses. Possible applications range from testing solids such as petroleum coke, lignite, and bituminous coal to viscous and liquid samples, such as tar or marine residual / bunker fuels of all various types. Combined with its outstanding precision, the vario MACRO cube is a versatile and reliable workhorse for the analysis of soils, fossil fuels, and derived products in unattended 24/7 operation.

Highlights of the vario MACRO cube

Highest versatility in a macro elemental analyzer

for simultaneous, one sample CHNS, CHN, CNS, or CN determination in macro sized samples

Simultaneous CHNS determination with highest precision and accuracy

made possible by our unique Advanced Purge and Trap (APT) technology

Sample preparation reduced to a minimum

thanks to large sample volumes of up to 1.5 g

Highest sample throughput

thanks to the integrated autosampler with up to 120 positions and low maintenance requirements

Features

Highest versatility in a macro analyzer

The vario MACRO cube is designed for simultaneous determination of CHNS in samples up to the gram range, and represents the world’s first analyzer to make this possible in a single, fully-automated step. The analyzer can be set up in CHNS, CHN, CNS, or CN mode to ensure an optimal configuration, tailor-made to your analytical demands. For even higher versatility in your analysis, the addition of optionally available upgrade kits for the detection of oxygen, chlorine, total inorganic carbon (TIC), and total organic carbon (TOC) is possible at any time.

Simultaneous CHNS determination with highest precision and accuracy

The vario MACRO cube guarantees blank-free sample transfer thanks to our patented ball valve sample introduction, resulting in analysis results with highest precision and accuracy. The use of our Advanced Purge and Trap (APT) technology enables the instrument to measure samples with even the most challenging C:N elemental ratios of up to 7,000:1. Apart from that, the instrument is ideal suited for highly precise hydrogen concentration measurements.

Sample preparation reduced to a minimum

Save valuable time in sample preparation! The vario MACRO cube can handle large sample volumes of up to 1.5 g which allows analyzing even inhomogeneous matrices without time-consuming sample preparation like grinding or milling. In addition, the large sample weight allows the determination of smaller element concentrations, which accounts for the vario MACRO cube’s wide detection range.

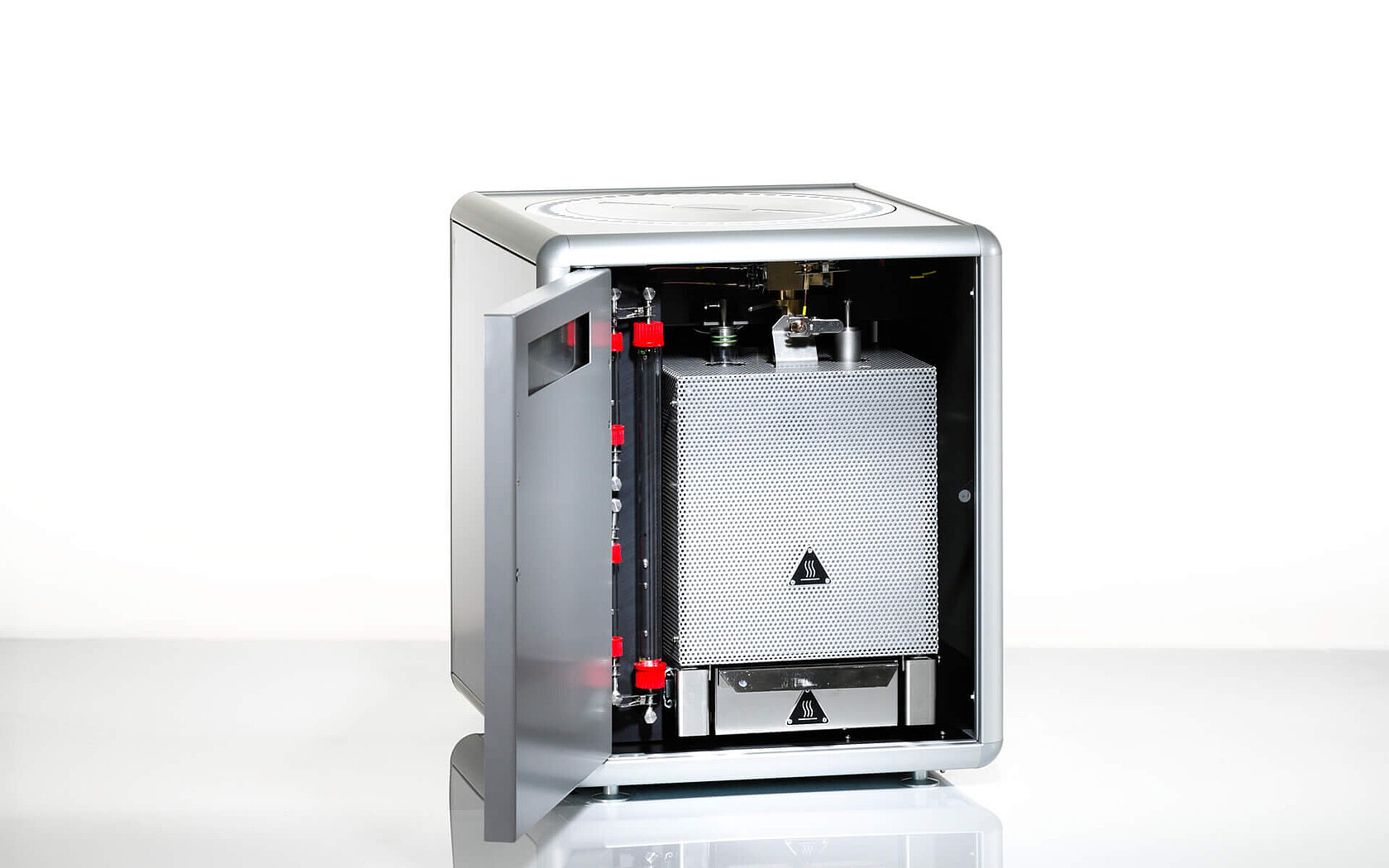

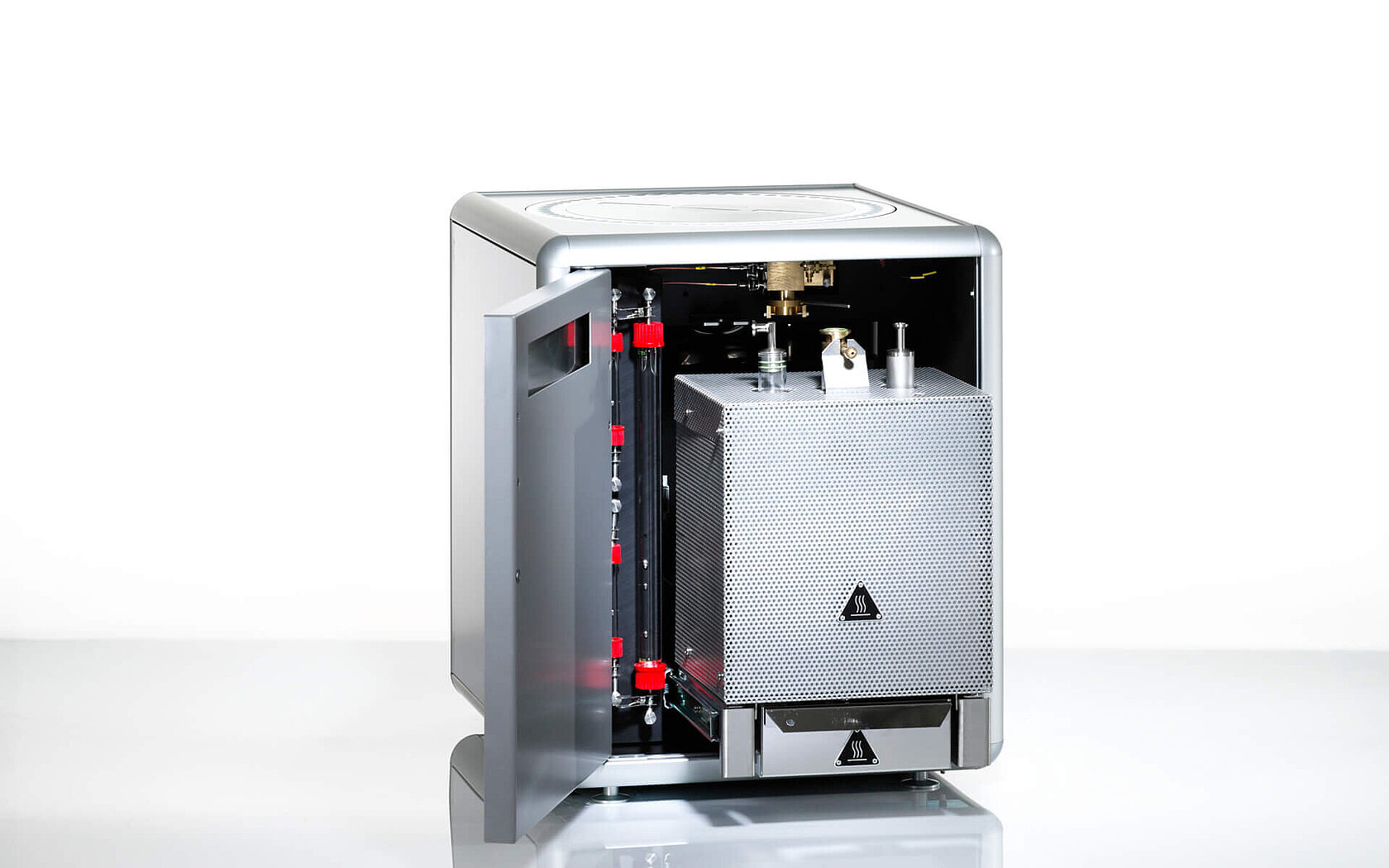

Highest sample throughput and low maintenance through design

The vario MACRO cube can be equipped with a large autosampler with up to 120 positions that is reloadable at any position and time, enabling a blank-free sample transfer and unattended 24/7 operation with highest sample throughput. The long-term stable calibration reduces contact time with the instrument, as no calibration samples prior to analysis are required. This results in extremely low maintenance and highest system uptime. Whenever maintenance is necessary though, our user-friendly clamp connections system ensures a tool-free maintenance experience, while the slide-out furnace gives access to all important parts and guarantees a comfortable working posture.

Future-proof thanks to 10 years guarantee

Thanks to the outstanding robustness and longevity of our vario MACRO cube, we grant a 10-year guarantee on the high-temperature combustion furnace and the thermal conductivity detector cell of the thermal conductivity detector (TCD). With our long-term oriented dedication to technical support, we provide spare parts for a minimum of 10 years. This results in outstanding low total cost of ownership, giving you confidence in return of investment.

Product details

The vario MACRO cube is optimized for the analysis of:

CHNS

CHN

CNS

CN

N

O*

Cl*

TIC*

TOC*

* optionally available

Weighing range

Largest weighing range spanning from micro (<1 mg) to macro (up to 1,500 mg), depending on sample requirements

Element concentration range

Largest dynamic range of element concentrations and element ratio

C: up to 100 mg (up to 150 mg*) absolute, from 0 - 100 %

H: up to 15 mg absolute, from 0 - 100 %

N: up to 100 mg absolute, from 0 -100 %

S: up to 18 mg absolute, from 0 - 100 %

O*: up to 6 mg absolute, from 0 - 100 %

Cl*: up to 1.2 mg absolute, from 0 - 100 %

Precision

< 0.1 % absolute (100 mg glutamic acid), depending on sample type, analysis mode, and configuration

Analysis time

~ 3-4 min per element, self-optimizing according to element content and sample weight. Depending on sample type, analysis mode, and configuration.

* optionally available

High-temperature combustion unit

Quantitative sample digestion at up to 1,200 °C, or 1,800 °C at the point of combustion when tin foil is used, with a ten-year furnace warranty. This is the prerequisite for 100 % recovery, even when dealing with samples that are difficult to combust - jet injection of oxygen directly to the sample leads to the highest oxygen concentrations at the point of combustion, as well as low gas consumption.

Advanced Purge and Trap (APT) technology

Separation of gaseous components on up to three specific columns for perfect separation without overlap, and automatic optimization of the analysis time.

Detector

- Thermal Conductivity Detector (TCD)

- Infrared Detector* for sulfur and oxygen

- Electrochemical Detector* for chlorine

Sample introduction

Integrated 60, 80*, or 120* positions autosampler (for solids and liquids in capsules), reloadable during analysis

Maximum furnace temperature

1,200 ° C (whereby 1,800 °C is briefly reached at the combustion point when using tin foil)

Instrument control

Windows® based vario MACRO cube operating software with LIMS integration and auto sleep and wake-up function for automated and unattended overnight operation. 21 CFR Part 11 functionality available.*

Required gases

Helium and oxygen

Dimensions

48 x 55 x 57 cm (W x D x H)

* optionally available

Electronic balance:

Balance and elemental analyzer form a system. We offer analytical balances from the leading manufacturers with our instruments. Please contact us for further information.

Sample former and pressing tools:

For simplified sample preparation, we offer a manual tool for compressing samples in tin foil or cups, and a mechanical press for the preparation of pellets with paper wrapping.

Capsule sealing press:

Tool for the exact dosing and gas-tight sealing of tin or silver capsules, for liquid and sensitive samples.

Downloads