Best practices for sample preparation in elemental analysis

When it comes to elemental analysis, accurate and reproducible results begin with a critical step: sample preparation. Whether you are analyzing solids or liquids, plant material or synthetic compounds, following best practices can make all the difference between reliable data and questionable outcomes. In this article, we will walk you through essential tips for preparing your samples correctly, from drying to weighing and everything in between.

Should I homogenize my sample?

In any case you have to make sure that your sample is representative of the whole. For pure chemicals or powders this is mostly the case, other samples need grinding or milling. A macro elemental analyzer simplifies the homogenization process, as it allows a sample weight in the hundreds of milligrams range up to the gram range. Coal, soil or food samples often need to be ground with a special milling device.

Should I dry my sample?

In almost all cases, the answer is yes. While pure chemicals may already be dry, other sample types need preparation:

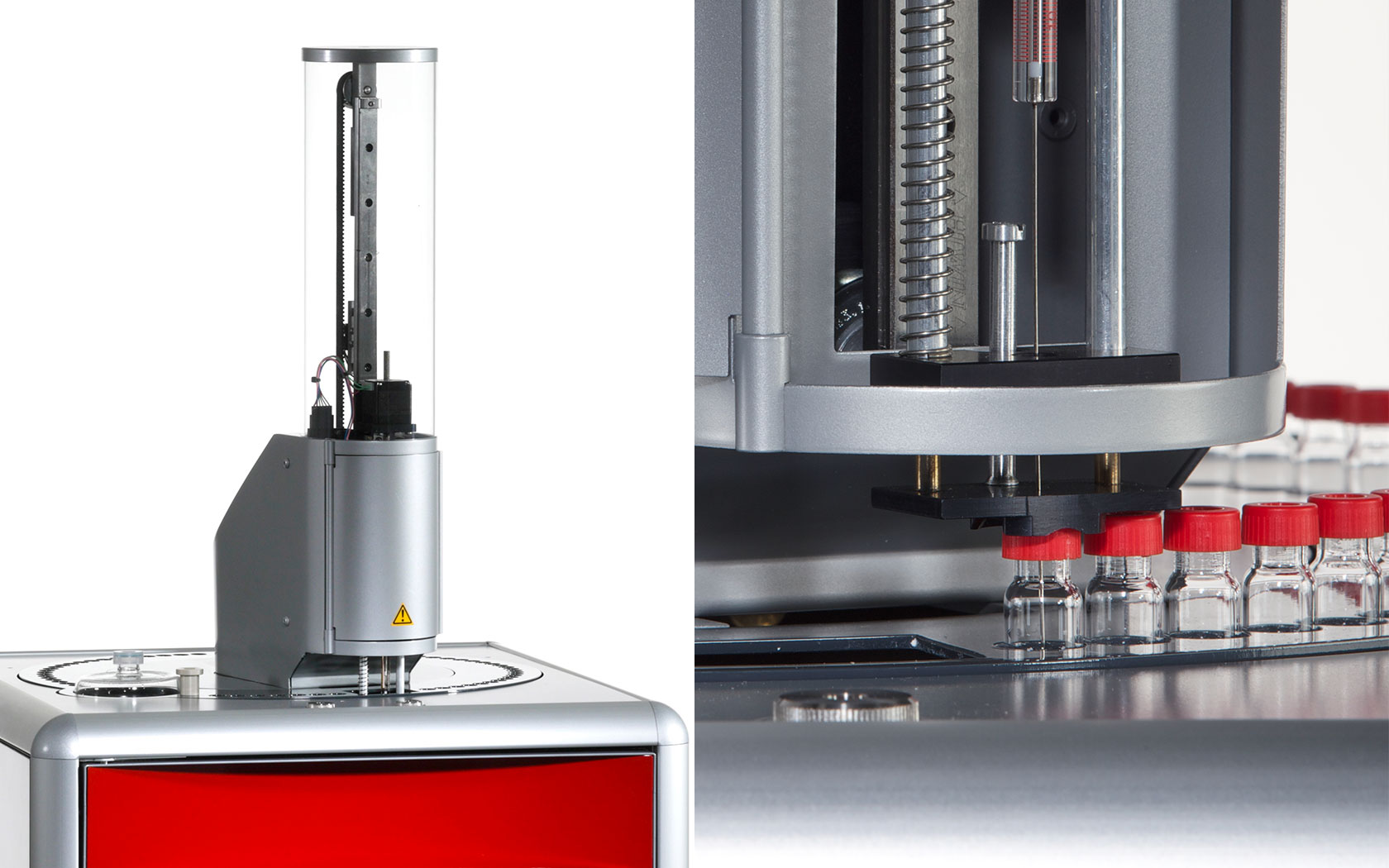

Hygroscopic substances should be sealed in gas-tight capsules. For this task, we recommend using our capsule sealing press made for the exact dosing and gas-tight sealing of capsules - ideal for liquid and sensitive samples. To protect samples from contact with air, the capsule can also be flushed with inert gas or even be closed in a glove box.

Samples such as coal, plant material or slurries require drying before analysis. Otherwise, the humidity must be known, since moisture affects both the measured weight and the hydrogen content in CHNS analysis. This can lead to errors if not accounted for.

If the sample humidity is known exactly, the software can compensate for the amount of water in the sample.

Do I need additives for better combustion?

In the past, additives like vanadium pentoxide were used to enhance combustion, but their toxicity and the evolution of modern technology have rendered them obsolete. Today’s instruments, like Elementar’s elemental analyzers, operate at optimized temperatures (e.g., 1150 °C) to ensure complete combustion. Therefore, additives are usually unnecessary.

For samples that are difficult to combust (graphite, coal…) or contain a large amount of halogens (i.e. salt) in CHNS mode , adding a small amount of tungsten trioxide (WO₃) to the sample container can help crack complex matrices and improve analytical accuracy. We offer tungsten(VI)-oxide powder in various container sizes – please refer to our Consumables Catalog for a complete list.

How do I wrap my sample properly?

a. Choosing the right sample container & sample size

For CHNS (Carbon, Hydrogen, Nitrogen, Sulfur) analysis, tin boats are the standard. We provide a broad range of boat sizes and shapes tailored to different sample types. Please refer to our Consumables Catalog for a complete list of available sample containers for your analyzer.

Also, choosing the right sample size is key: smaller samples and boats reduce maintenance frequency by lowering residue build-up in the combustion system. For more information on how to find the right sample weight, please read our blog article „Finding the right sample weight for elemental analysis“.

b. Proper wrapping technique

Proper wrapping ensures combustion efficiency and protects your instrument. Watch the video below to learn how to wrap solid samples properly.

For simplified sample preparation, we offer manual tools for compressing samples in tin foil or cups, and a mechanical press for the preparation of pellets with paper wrapping. Please refer to our Consumables Catalog for a complete list of auxiliaries.

How do I handle liquid samples?

a. Occasional liquid samples

If you analyze liquid samples infrequently, use tin capsules in combination with a capsule sealing press:

Tare the balance with the empty tin capsule in place

Pipette the liquid into the capsule

Flush with inert gas

Seal it using the capsule press

Weigh the sealed capsule

Place it in the instrument’s sample carousel like a solid sample

b. Frequent liquid analysis

For labs analyzing mostly liquids, an automated liquid sample feeder is a game-changer:

No more weighing

No tin capsules

Fewer consumables

Greater throughput and reproducibility

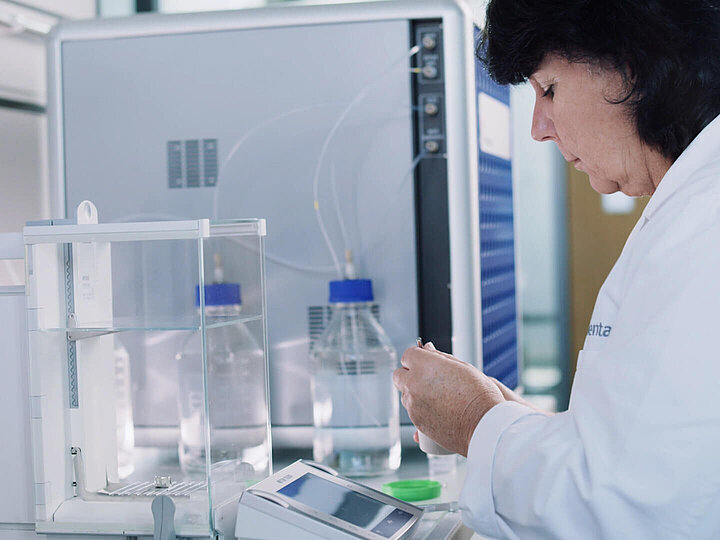

How do I weigh my sample correctly?

a. Choosing the right balance

Your choice of balance depends on two key factors: your application and your budget. If you are working with samples in the lower milligram range, a 6-digit microbalance is essential to ensure precision. For larger sample sizes, a standard analytical balance will suffice and is significantly more budget friendly.

b. Optimizing the weighing environment

Accurate weighing involves more than just using a precise balance - it also requires careful control of the surrounding environment. Even the most advanced analytical balances can yield unreliable results if environmental factors are not properly managed. Below are key considerations for optimizing the weighing environment:

- Temperature and humidity control

Temperature fluctuations and varying humidity levels can significantly impact the accuracy and stability of analytical balance readings. Analytical balances are highly sensitive instruments and should always be operated within the manufacturer’s specified temperature range to ensure reliable results. - Minimizing air currents and vibrations

Air movement from ventilation systems, doors opening, or people walking nearby can create drafts that affect balance stability. Vibrations from heavy equipment or even foot traffic can also lead to fluctuating measurements. Therefore, use vibration-dampening tables or anti-vibration pads and make sure to position the balance away from high-traffic areas and machinery. - Controlling magnetic and electrostatic interference

Magnetic fields and electrostatic charges can exert forces on the weighing pan or sample, distorting the measurement. Avoid placing balances near electrical equipment or magnets. Use anti-static devices (e.g., ionizing bars or brushes) and ensure proper grounding of both the balance and operator.

For maximum precision, use a dedicated weighing room or enclosure:

- Ideally located in a quiet, temperature-stable, and vibration-free area The ideal room for weighing samples in the lower milligram range is located in the basement. The solid foundation of the building will ensure less vibration and a better weighing result. If this is not possible, pick the corner of a room, close to the walls.

- Minimize airflow using draft shields or enclosures.

- Use solid, stable countertops or purpose-built weighing tables.

- Adjust for gravitational changes by recalibrating, if moving the balance location.

Implement strict calibration and maintenance protocols to ensure consistent performance over time.

Conclusion

Sample preparation is not just a preliminary step - it is the foundation of accurate elemental analysis. By choosing the right tools, environment, and methods for your sample type, you ensure that your data is not only precise, but also trustworthy.