Intertek Food Services has used the BiovisION Honey LC-IRMS system to minimize downtime in its honey analysis work

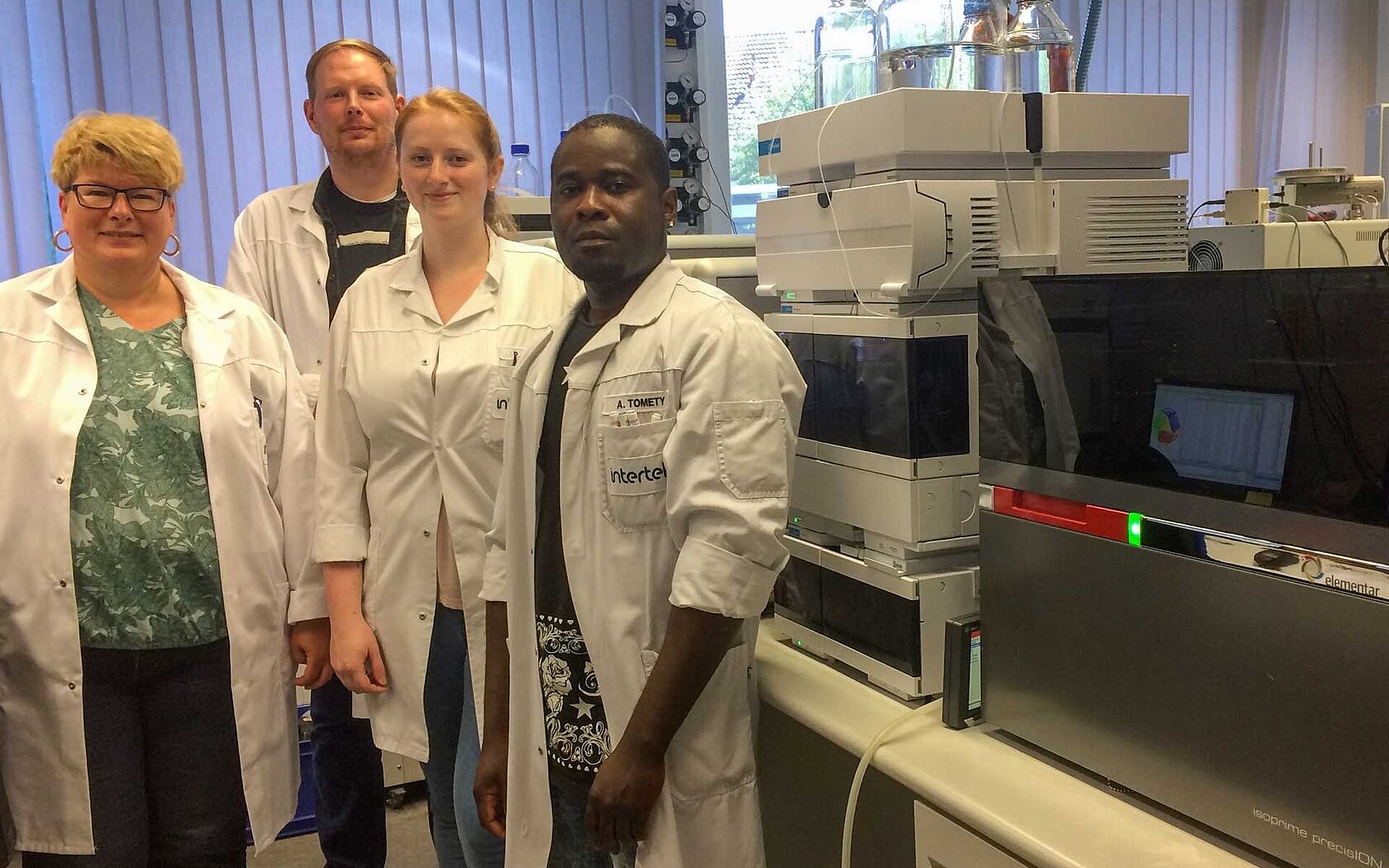

Ulrike Burmester is the senior lab supervisor for authenticity stable isotope and NMR food services at Intertek Food Services GmbH, based in Bremen, Germany. In this role, Ms Burmester is responsible for managing the company’s honey and syrup authenticity testing, a major service provided by Intertek to various stakeholders down the supply chain of honey producers, for the ultimate purpose of delivering a higher-quality product to consumers.

The detection of honey adulteration by identifying illegally added C4 sugars has been a standard method for many years, but Intertek have built on this by successfully commercializing a new technique to detect honey adulteration with C3 and C4 sugars1. This technique utilizes a liquid chromatograph to separate honey into its carbohydrates constituent, followed by the oxidation of these carbohydrates to form CO2. The 13C/12C isotope ratio of the separated carbohydrates can then be measured, and any possible honey adulteration detected.

This powerful technique allows otherwise undetectable adulterations to be uncovered, helping to protect businesses and consumers. However, the LC-IRMS analytical technique that this method relies on has historically been fraught with difficulties, due to the short maintenance cycles and significant instrument downtime. Despite these issues, Intertek is measuring approximately 15,000 LC-IRMS samples a year, maintaining a reliable and fast service for customers via supplementary instrument capacity and work assignments over weekends.

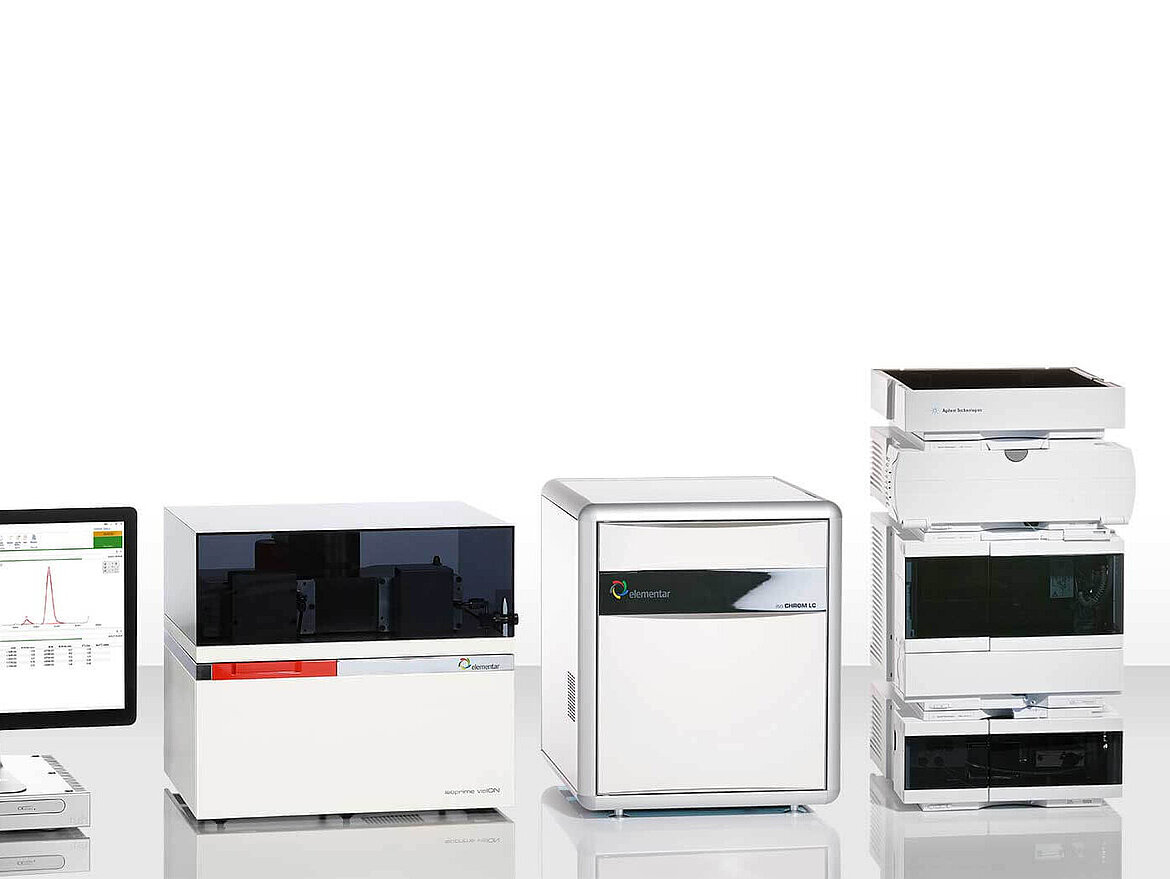

Facing these conditions, Intertek sought a more robust 24/7 instrument to reduce production costs and downtime, which is why the company was keen to take part in the beta test for Elementar’s first LC-IRMS prototype, the iso CHROM® LC, in 2017. The iso CHROM® LC is part of the BiovisION Honey LC-IRMS system which was adapted and specifically tailored, in close cooperation with Intertek, for the needs of a high-throughput analytical laboratory with a focus on honey and syrup samples.

The iso CHROM® LC uniquely utilizes high-temperature combustion for the conversion of separated carbohydrates to CO2, rather than the wet-chemical oxidation technique that Ms Burmester and her team had been using for several years. After the careful testing and evaluation of every aspect of the iso CHROM® LC, the team came away extremely satisfied by the instrument’s performance, recognizing the opportunity it provided to implement a significantly more robust system for the Intertek laboratory.

Speaking about her experiences using the iso CHROM® LC installed at Intertek, Ms Burmester said:

So far, the Elementar LC-IRMS instrument has been very impressive for C4 and C3 honey adulteration analysis. The high-temperature combustion method means that no aggressive chemicals such as sodium persulfate are required, which can lead to blocked tubes, noisy baselines and instrument downtime.

The instrument hardware is easy to maintain and offers automatic routines for performance checks running overnight. We are now much closer to running samples 24/7.

About Intertek Food Services

Intertek Food Services is a leading total quality assurance provider to industries worldwide, with a network of more than 1,000 laboratories and offices, and over 46,000 people in more than 100 countries.

Intertek delivers innovative and bespoke assurance, testing, inspection, and certification solutions for its customers’ operations and supply chains, providing total quality assurance expertise - delivered consistently with precision, pace, and passion - to enable its customers to power ahead safely.

Instrumentation installed: | BiovisION Honey+ system equipped with an iso CHROM® LC

BiovisION Honey+ system equipped with an iso CHROM® LC

BiovisION Honey+ system equipped with an iso CHROM® LC |

Contact details: | Website: www.intertek.com/food |

References: | 1 Elflein, L., & Raezke, K. P. (2008). Improved detection of honey adulteration by measuring differences between 13C/12C stable carbon isotope ratios of protein and sugar compounds with a combination of elemental analyzer-isotope ratio mass spectrometry and liquid chromatography-isotope ratio mass spectrometry. Apidologie, 39(5), 574-587. |