Future labs: Balancing automation, sustainability, and networked intelligence

Is the “dark lab” already within reach? Or will it still be a while before we can turn off the lights in the laboratory of the future because all the equipment is automated?

The laboratory of the future, in which mills, sieves, balances, and elemental analyzers communicate directly and work together automatically, is no longer so far away. New technologies such as artificial intelligence (AI), robotics, digital networking, and sustainable infrastructures are changing the way research is conducted. If only a few human interventions are required, we can leave the lights off and call it a “dark lab,” analogous to the “dark factory” in the automotive industry.

Whether it is the analyst's dream or nightmare to have only a supervisory role and occasionally perform the increasingly rare maintenance of the equipment, the path to this goal has already been set. Many of the building blocks for this are already on the market or in development, as automation is also finding its way into the laboratory. Gradually, the individual pieces of the puzzle will come together until a largely automated process is possible, from sample receipt to report creation and evaluation. Of course, further development in this direction requires investment, which will initially be realized in the procedures that are most time-consuming and most frequently performed in the laboratory. This is where the cost pressure is highest; niche technologies will follow and benefit from previous developments.

So what steps towards a “dark lab” are necessary and already in development?

Automation and AI: The lab of the future

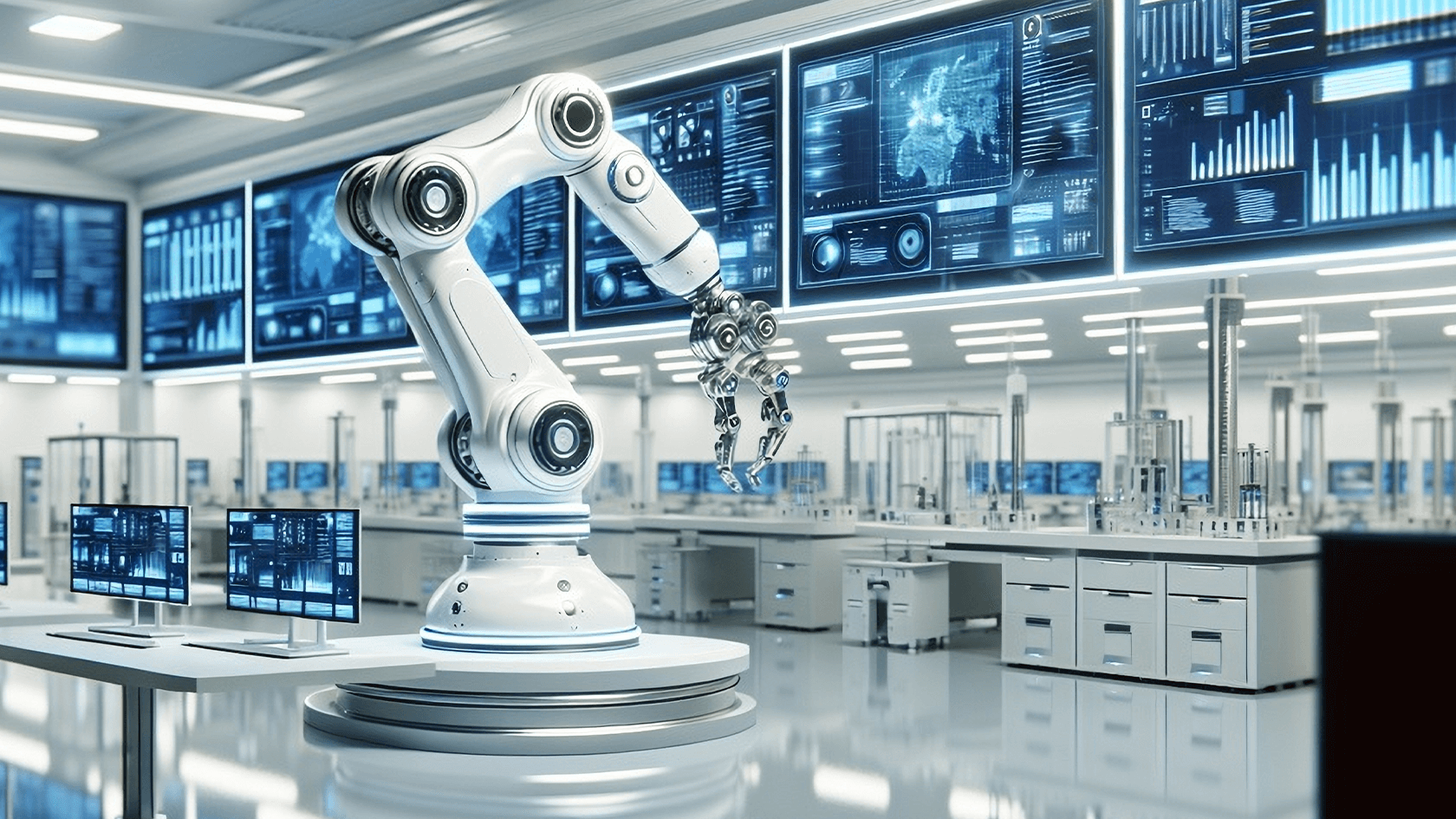

Laboratory automation is no longer fiction, but reality: robotic arms, sensors, and intelligent pipetting machines are taking on more and more tasks. One new technology looms large over all future development topics: the use of artificial intelligence. Evaluating data with the help of AI enables experiments to be carried out in a faster, more precise, and more reproducible manner.

With the emergence and easy availability of large language models (LLMs) such as ChatGPT or the European Mistral LeChat, it is only a matter of time before AI is used in every analysis device. Much is still in the early stages of development, but it is already clear that the creation and optimization of specific measurement sequences, statistics, and the evaluation of chromatograms and mass spectra will be significantly accelerated. Manufacturers who do not integrate such a feature in the future will find themselves at a disadvantage. To all students who hope to neglect method development during their studies, please note: A thorough understanding of the underlying processes is still essential!

Holistic communication in focus

The digital laboratory, or smart lab, utilizes cloud technologies, Internet of Things devices, and data platforms to connect laboratories worldwide. This has posed challenges for the industry, which is dominated by medium-sized companies, as long-established dogmas had to be overcome, long-standing processes questioned, and new paths taken. The industry association of analytical instrument manufacturers, Spectaris, has made a particularly valuable contribution here, working with the OPC Foundation and committed member companies to drive forward the development of the OPC-LADS interface. This is already being used in numerous devices today, alongside other standards. More will follow.

Within our company, our analytical instruments have been communicating with each other for quite some time now. Our mass spectrometers, elemental analyzers, and Agilent gas chromatographs for stable isotope analysis are also fully integrated in terms of software. For users, this means that a single user interface allows them to control all relevant functions. This is where the complete digitalization of the cube platform and our long-standing partnership with Agilent come into play. For many years, all functions of our devices have been monitored automatically. Whether flow, temperature, pressure, database backup, or the analysis sequence, the software reliably controls and monitors all functions.

And how green is it in the “dark lab”?

In addition to automation and networking, another requirement for elemental analysis is linked to the laboratory of the future. Environmentally harmful techniques are increasingly being replaced by more sustainable and ultimately more cost-effective methods. Traditional techniques have certain strengths, but the pressure on laboratories to seriously consider alternatives is increasing when hazardous waste is produced and its disposal is associated with high costs.

Examples include replacing the Kjeldahl method for protein determination with the Dumas combustion method and determining total organic carbon (TOC) as an alternative to chemical oxygen demand (COD) in water.

Rapid modernization is often hampered by long-established written and unwritten industry standards. DIN, ISO, ASTM, and other organizations are currently working to ban harmful chemicals from everyday laboratory use or at least to allow established alternatives.

In conjunction with automation, this means that the laboratory of the future will not only be digital and highly automated, but also “green” – with optimized energy consumption, minimized waste, intelligent equipment management, and a circular economy in the laboratory environment.

Challenges and outlook

The laboratory of the future is more than just technological progress—it represents a cultural shift in science. Automation, digitalization, and sustainability must be understood as a single entity.

Better communication between devices, environmentally friendly and sustainable methods, and the ergonomic design of modern systems will make working in the laboratory of the future easier, faster, and safer.

At the same time, the role profiles of laboratory staff are changing: fewer monotonous tasks, more digital skills, more responsibility in handling data and automated systems. Employees must learn to see technology not as a replacement, but as a support—as a tool that expands their expertise.

If the results are right, we can look forward to the future in the Elementar laboratory!

Do not miss any new articles

NEWSLETTER

We will constantly publish new blog articles. Register for our newsletter to stay up-to-date and get informed about latest blog articles, news and trends.