Alternative fuels for greener aviation

The aviation industry experienced a significant slump worldwide during the coronavirus pandemic between 2020 and 2022. The aviation industry has since recovered, and global figures have already exceeded pre-pandemic levels. In a global comparison, the departure rate increased by 4.5% between 2024 and 20251.

Global CO2 emissions and demands for fuel are rising accordingly. By 2030, aviation will be responsible for 3.5% of global energy-related CO2 emissions (up from 2.5% today).2

In 2021, airlines, manufacturers, air navigation service providers and airports worldwide agreed on a climate protection strategy and set a specific target: global CO2 emissions in aviation are to be reduced by 50% by 2050.

Various measures are being considered, including propulsion technologies using electricity or hydrogen as well as sustainable aviation fuels (SAFs) to reduce carbon emissions from aviation. SAFs are sustainable kerosene that could more or less replace traditional kerosene almost one-to-one, without the need to redesign turbines and aircraft.

SAFs are produced without the use of fossil raw materials such as crude oil, which is common in traditional kerosene. They can be produced from biogenic residues such as used cooking oils or fats. The addition (“drop-in”) of lower-carbon SAF to fossil kerosene could be important in the global sustainability strategy for aviation. The maximum blending percentage of SAF permitted is currently 50% - however, fuel standards are set to be adapted to allow the use of 100% SAF by 2030.3

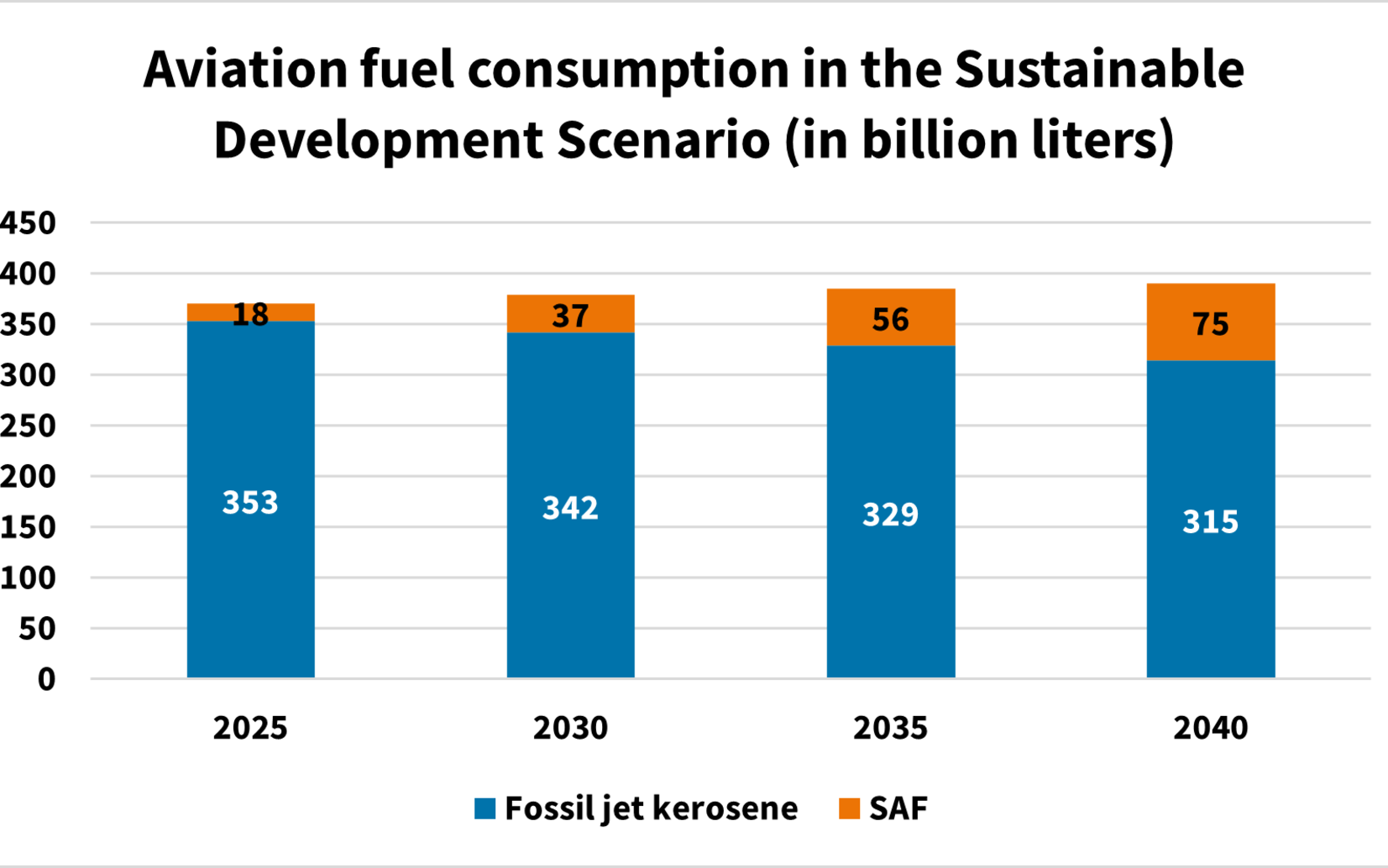

The IEA (International Energy Agency) even predicts that alternative fuels will account for around 10 % of global demand by 2030 and almost 20 % by 2040.

By 2050, that would be between 330-445 million tons of SAF.3

The production of SAF

ASTM International (American Society of Testing and Materials) has approved seven manufacturing processes for SAF in accordance with the ASTM D7566 standard.

The best known of these are the following four processes:

- The HEFA process (Hydrogenated Esters and Fatty Acids), a process that is currently the most widely used (88%), where the water is removed from vegetable oils, animal fats or used cooking oils to produce an oil. This is then refined in a similar way to crude oil.4

- The alcohol-to-jet process (AtJ), where biomass is first converted into ethanol and then into fuel.

- In the Fischer-Tropsch synthesis, a synthesis gas of carbon monoxide and hydrogen is converted into liquid hydrocarbons, from which kerosene can then be obtained. (However, both this and the AtJ processes are less common).

- The power-to-liquid process (PtL) is still in the development stage. This relies on regeneratively-generated energy from the sun or wind, CO2 and water. A synthetic gas is produced, which in turn can produce petrol or kerosene using the Fischer-Tropsch synthesis mentioned above.

The cost differences between conventional kerosene and sustainable fuels in terms of raw material costs, production technology and economies of scale are immense. However, government subsidies and private projects offer incentives to support the production of SAF.

According to studies by the ICAO (International Civil Aviation Organization), a complete replacement of conventional kerosene with alternative fuels would require annual investment in around 170 new production facilities by 2050 (around USD 15 to 60 billion per year).1 Securing the required quantities of raw materials, converting experimental to professional production facilities, new supply routes and competitive prices all play a major role in this.

Analytical quality control of SAF using CHNOS analysis

A decisive factor for the use of SAF in the aviation industry is the quality of alternative aviation fuels. In such a safety-critical industry, compliance with defined quality standards and internationally-recognized certifications is essential.

The elemental composition of sustainable feedstocks - such as various biomasses or waste fractions - is often subject to strong fluctuations. This directly influences the resulting fuel properties and their compliance with specification-relevant quality parameters. CHNOS analysis is a key analytical method for characterizing SAF: Sulphur and nitrogen contents are particularly critical as they can contribute to the formation of undesirable emissions and must be strictly controlled. Nitrogen and oxygen, on the other hand, can influence combustion properties.

The CHNOS values can also be used to calculate the calorific value - an important indicator of energy efficiency. The carbon content, in turn, allows conclusions to be drawn about CO₂ emissions during combustion and is therefore used for ecological assessment. Lastly, CHNOS analysis also supports monitoring and optimization of the SAF production process. Since sustainable aviation fuels can only actually contribute to environmental and climate protection if they meet strict sustainability criteria, analytical control is of central importance.

Outlook

The use of SAF and the associated replacement of kerosene still requires some planning and restructuring in terms of securing the required quantities of raw materials, expanding production facilities and creating supply routes, reducing prices and introducing standards and certifications.

The goal of climate-neutral aviation by 2050 is ambitious but appears to be achievable with current technological progress and targeted political will. A key prerequisite for this is the global standardization of regulatory frameworks, sustainability requirements and technical specifications.

In this context, CHNOS elemental analysis is becoming increasingly important: it forms the basis for the assessment of fuel quality, energy efficiency and emission characteristics of SAF. It also serves as a central tool for in-process optimization and quality assurance in SAF production. The CHNOS analysis thus makes an essential contribution to the technological scaling and ecological assessment of sustainable aviation fuels - and is an indispensable tool on the path to climate-friendly aviation of the future.

Find out more

Find out how and why CHNOS analysis plays an important role for quality control

DOWNLOAD YOUR COPY

Fill in the form to receive your download link per e-mail.

Your contractual consideration for the free provision of the download is the subscription to our personalized newsletter. By clicking on the “download now” button, you therefore declare your acceptance of the receipt of personalized newsletters by e-mail by Elementar India Pvt Limited and its group companies as well as the evaluation of your user behavior in this regard and - if available - the merging of this data with your data in our customer database.

In order to receive newsletters from our group companies it is necessary to transfer your above-mentioned personal data to these companies. The data transfer is contractually required.

You are aware that the subscription to our personalized newsletter represents the contractual consideration that you provide for the free provision of the download. You can unsubscribe from the newsletter at any time with effect for the future. You can object to the future use of your data for advertising purposes at any time. For further information, please refer to our privacy policy.

Do not miss any new articles

NEWSLETTER

We will constantly publish new blog articles. Register for our newsletter to stay up-to-date and get informed about latest blog articles, news and trends.