Efficient wastewater treatment and the role of TOC in process control

Wastewater treatment plants, often hidden on the outskirts of our cities and towns, play a critical role in our modern society. Their importance is undeniable: they enable the effective treatment of wastewater, a process that is essential to combat pollution and protect public health. However, they remain unnoticed by the majority of the population. In the following article, we will focus on this hidden but important infrastructure and shed light on the role of TOC (Total Organic Carbon) concentration in the process control of wastewater treatment plants.

Wastewater clarifiers – performance, efficiency, and the treatment environment

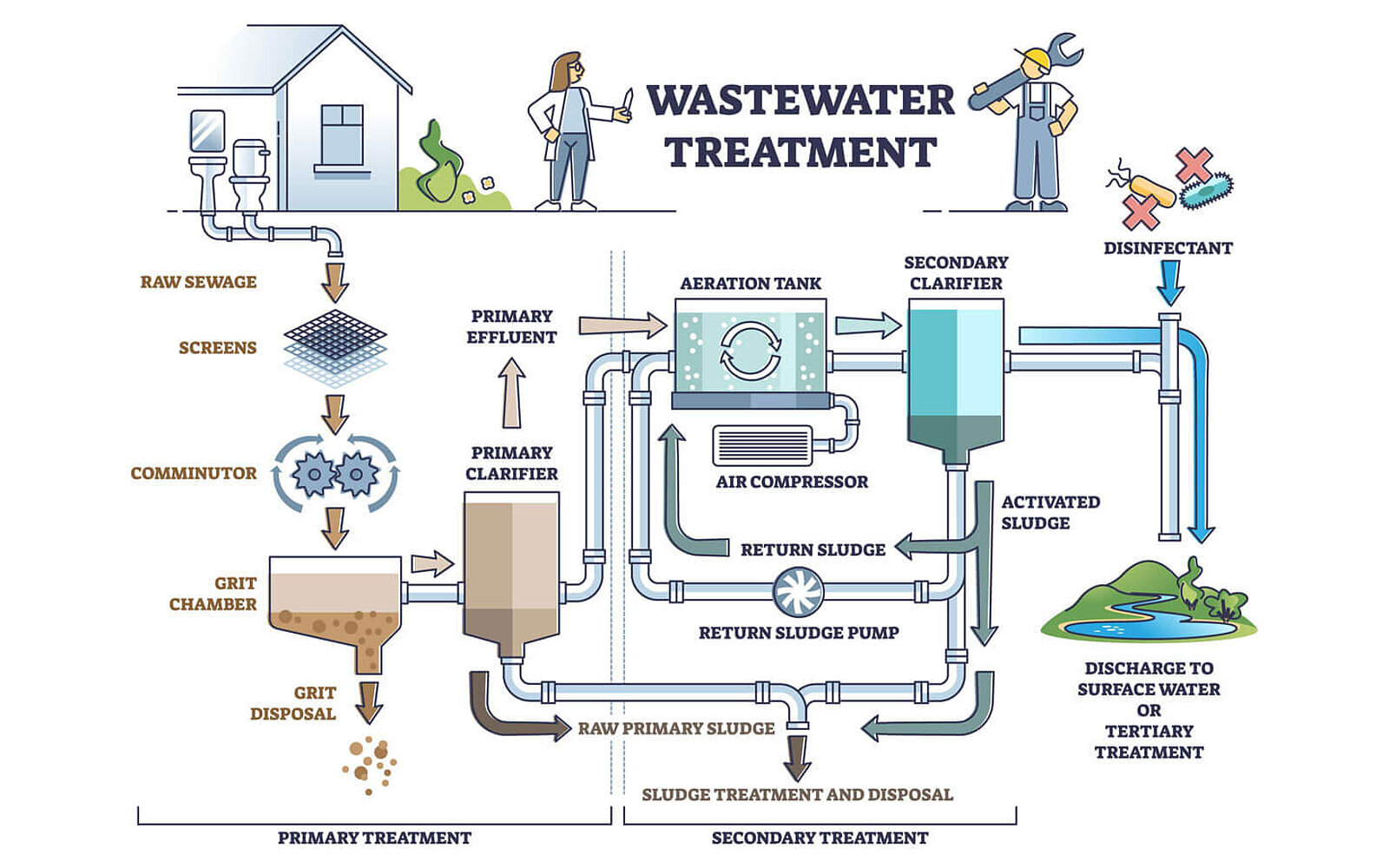

Clarifiers are an integral part of every wastewater treatment plant. This is where solids are removed from wastewater through gravity sedimentation. All clarifiers have two functional parts – a clarification area, where gravity sedimentation happens, and a thickening area, where the settled solids are accumulated to form a dense layer of sludge.

Primary clarification is where the physical process of removing solids before biological treatment takes place. Water enters the clarifier tank and floatable solids, also known as scum, are removed from the surface, whilst settleable solids, also called sludge, are collected on the bottom, and removed. Effluent intended for biological treatment leaves the clarifier over a weir.

Primary clarifier performance is measured by a tank’s total suspended solids (TSS), biological oxygen demand (BOD) and by the condition of the primary sludge, considering its volume, concentration, and septicity. When functioning as it should, a primary clarifier is expected to remove 90% to 95% of settleable solids (sludge), 40% to 60% of suspended solids (scum), 25% to 75% of bacteria and 25% to 50% of total BOD.

Organic measurement, such as BOD and chemical oxygen demand (COD) were developed to measure water quality. However, these methods are time consuming, ranging from hours to days, which limits how useful COD or BOD can be as process control parameters. That’s where total organic carbon (TOC) comes in. TOC allows for effective process control because results are generated much more frequently, which means that decisions concerning clarifier performance and efficiency can be made almost in real-time and more smartly.

Various factors affect clarifier efficiency, such as the type of solids in wastewater and where they come from, how long it takes to travel through the system, hydraulic detention time, the design of the tank and the condition of the equipment as well as the temperature of wastewater.

Temperature affects all biological processes. Optimum temperatures for bacterial activity are in the range of 25 °C to 35 °C. Biological oxidation rates peak at about 35 °C in most treatment systems. At temperatures higher than 35 °C, treatment efficiency decreases as bacterial floc formation reduces. Temperatures lower than 10 °C also affect the performance of biological processes, especially when it comes to nitrification efficiency.

Biological activity is influenced by temperature because of the depth of penetration of oxygen into the floc or film. Oxygen penetration increases as temperature decreases, since oxygen is not used as quickly at floc surfaces and greater numbers of organisms per unit surface can react.

Variations in temperature can make a big difference in the composition of microbial communities. The dominance of a particular species shifts depending on the constantly changing composition and quality of the wastewater. As temperature changes, one group of microorganisms becomes less active and can even die off, whilst another group becomes dominant. Psychrophiles grow in the 0 to 20 °C range, with an optimum of 10 to 15 °C. Mesophiles, which are the species most found in wastewater treatment, grow in the 10 to 45 °C range, with an optimum of around 30 to 35 °C. Thermophiles, found in compost piles and other high-temperature environments, grow in the 40 to 75 °C range, with an optimum growth rate at 55 to 65 °C.

Temperature is, of course, just one environmental factor that affects wastewater treatment. But given its importance for biological processes, it’s imperative for facility operators to maintain the right temperatures. This is why process engineers use temperature as a key parameter in the designs of any biological wastewater treatment plants and adapt it to local climatic conditions. In cold environments, insulation of tanks is important to keep temperatures ideal. In warm climates, wastewater often needs to go through a cooling process.

Conclusion

Wastewater treatment plants are critical to maintaining a clean and healthy environment. The efficiency of these plants depends on a variety of factors, including process control through TOC analysis and maintaining optimal operating parameters such as temperature. By continuously monitoring and adjusting these parameters, wastewater treatment plant operators can ensure that their plants operate efficiently and make a positive contribution to protecting our environment.

Find out more

Whitepaper: TOC vs. BOD & COD

If you would like to learn more about the specific safety, reliability and environmental performance benefits that TOC can deliver compared to BOD and COD measurement for wastewater analysis, read our whitepaper:

DOWNLOAD YOUR COPY

Fill in the form to receive your download link per e-mail.

Your contractual consideration for the free provision of the download is the subscription to our personalized newsletter. By clicking on the “download now” button, you therefore declare your acceptance of the receipt of personalized newsletters by e-mail by Elementar India Pvt Limited and its group companies as well as the evaluation of your user behavior in this regard and - if available - the merging of this data with your data in our customer database.

In order to receive newsletters from our group companies it is necessary to transfer your above-mentioned personal data to these companies. The data transfer is contractually required.

You are aware that the subscription to our personalized newsletter represents the contractual consideration that you provide for the free provision of the download. You can unsubscribe from the newsletter at any time with effect for the future. You can object to the future use of your data for advertising purposes at any time. For further information, please refer to our privacy policy.

Do not miss any new articles

NEWSLETTER

We will constantly publish new blog articles. Register for our newsletter to stay up-to-date and get informed about latest blog articles, news and trends.