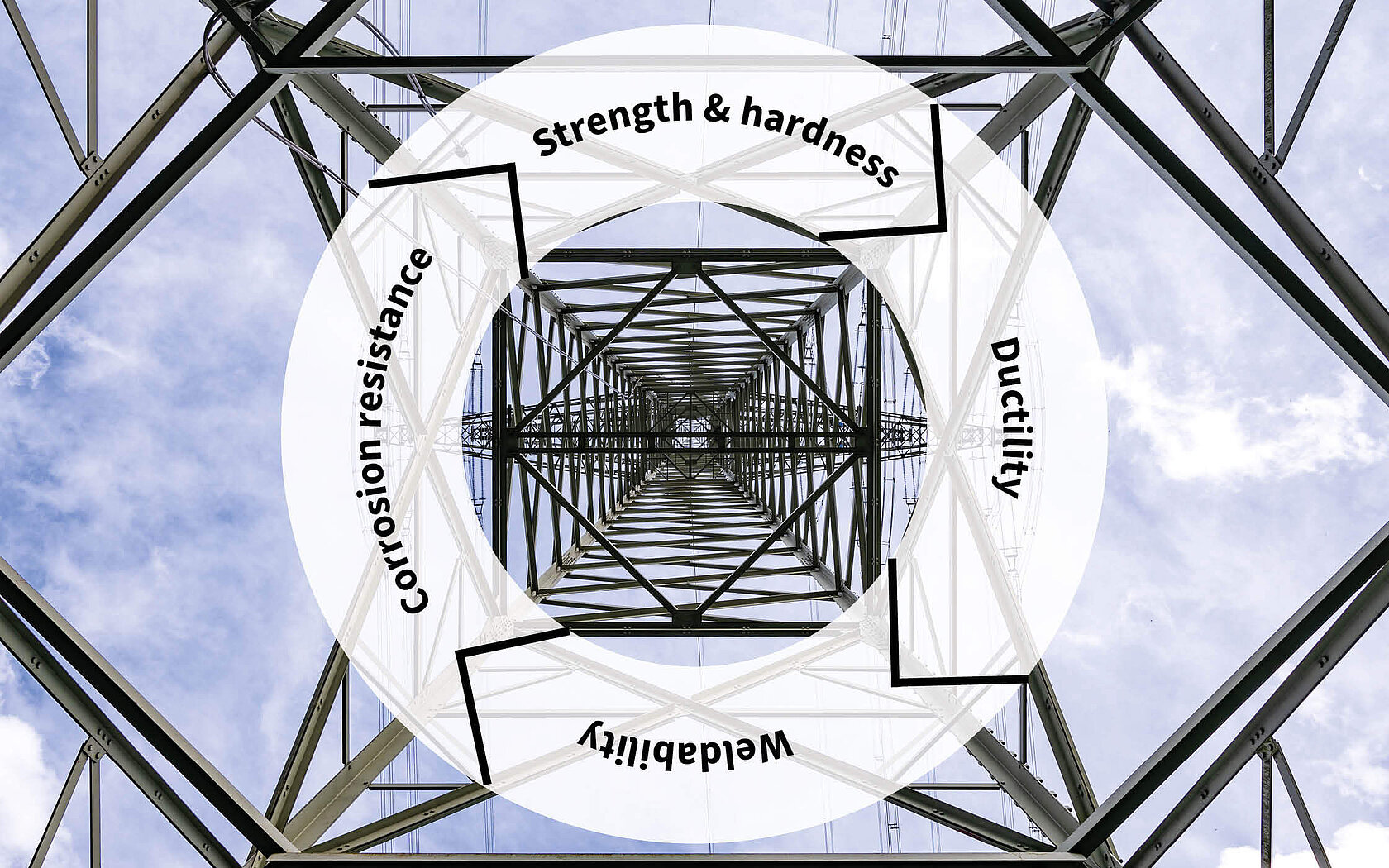

The carbon content in steel - a decisive factor for material properties

Steel is a material that consists mainly of iron with only a small proportion of carbon. It is one of the most versatile construction materials and can be recycled almost indefinitely. The carbon content is a crucial alloying element that significantly influences the mechanical properties - quality control is therefore essential to ensure that the materials used have the right properties.

The influence of the carbon content in steel

Strength and hardness

As the carbon content increases, so does the strength and hardness of the steel. This makes it ideal for applications that require a high load-bearing capacity, such as tool steels or components in machines. From a carbon content of 2 %, the material is referred to as cast iron and no longer as steel. Cast iron has a high strength, but can no longer be plastically formed, i.e. forged or rolled.

Ductility

The ductility, i.e. the ability of a material to deform plastically, decreases with increasing carbon content. This can make processing more difficult and increase the risk of breakage. Ductile materials are important in the construction and automotive industries, for example. In the case of an accident, a car should

Weldability

Not every steel can be welded. Weldability tends to decrease with increasing carbon content, with steels up to a carbon content of approx. 0.20 % being considered weldable. This is because the increasing hardness makes the steel more susceptible to cracking. The equivalent carbon content (CEV) is used for a precise assessment of weldability, a comparative parameter that provides information on the weldability of steels and takes the influence of other alloying elements into account.

Corrosion resistance

High-alloy chromium steels with a chromium content of at least 10.5 %, which form a protective passive layer, are considered corrosion-resistant. These steels may only contain very little carbon (less than 0.1 %), as chromium carbides can form with higher carbon contents. These carbides bind the chromium so that it is no longer available for the formation of the protective passive layer, which has a negative impact on corrosion resistance.

Examples of different types of steel and their carbon content

Carbon content in structural steel

More than half of the steels produced worldwide are structural steels. These are mainly used for the construction of buildings and machinery where there are no special requirements, i.e. in terms of strength or corrosion resistance. Structural steels often have a very low carbon content and therefore have a certain ductility. Normally, structural steel can deform by around 25 % before it cracks. This is important in the construction industry so that excessive stresses on components can be revealed by deformation.

Carbon content in stainless steel

Stainless steel is a collective term for alloyed or unalloyed steels with a high degree of purity. Steel refiners such as chromium or other elements are often used as alloy components for special requirements such as corrosion resistance. Accordingly, stainless steels have a low carbon content. One example of the influence of carbon on material properties is the stainless steels AISI 316 and AISI 316L. The elemental composition of this steels only differs in terms of their carbon content. 316L contains less carbon (the “L” stands for “low carbon”) and therefore has better weldability and less intercrystalline corrosion.

Carbon content in duplex steel

Duplex steels are among the rust and acid-resistant types of steel and combine the properties of stainless chromium steels and stainless chromium-nickel steels. Accordingly, they contain very little carbon. More relevant than the carbon content in duplex steel, however, is the alloying with nitrogen (up to 0.3 %) - this makes the difference between a high-alloy steel and duplex steel. The nitrogen acts as a hardening element and increases the mechanical strength. Nitrogen also improves resistance to pitting and crevice corrosion.

Carbon content in cast iron

Cast iron is an iron alloy with a high carbon content (> 2.06 %), which distinguishes this material from steel. Due to its carbon content, cast iron is hard and brittle and therefore cannot be forged. However, it has a significantly lower melting point than steel and is therefore cast in a mold. Compared to steel, cast iron can contain more impurities and is therefore cheaper than steel.

Carbon content in hardenable steel (tranformation hardening)

Hardening steel increases its mechanical resistance by specifically changing its microstructure. This can be achieved, for example, by heat treatment followed by rapid cooling. However, for a steel to be hardenable at all, it must have a carbon content of at least 0.2 %.

Get an insight into the carbon and sulfur concentration analysis of various steel samples carried out with our inductar® CS cube elemental analyzer.

DOWNLOAD YOUR COPY

Fill in the form to receive your download link per e-mail.

Your contractual consideration for the free provision of the download is the subscription to our personalized newsletter. By clicking on the “download now” button, you therefore declare your acceptance of the receipt of personalized newsletters by e-mail by Elementar India Pvt Limited and its group companies as well as the evaluation of your user behavior in this regard and - if available - the merging of this data with your data in our customer database.

In order to receive newsletters from our group companies it is necessary to transfer your above-mentioned personal data to these companies. The data transfer is contractually required.

You are aware that the subscription to our personalized newsletter represents the contractual consideration that you provide for the free provision of the download. You can unsubscribe from the newsletter at any time with effect for the future. You can object to the future use of your data for advertising purposes at any time. For further information, please refer to our privacy policy.

Quality control by means of precise determination of the chemical composition of steel

Due to the major influence of the elemental composition, such as the carbon content on steel properties, characterization and quality control is essential to ensure that the materials used have the right properties. With material analysis, deviations from specifications can be detected and corrected at an early stage to avoid material-related problems and failures. Furthermore, material analysis can provide conclusions about the cause of material problems or product failures if problems have already occurred.

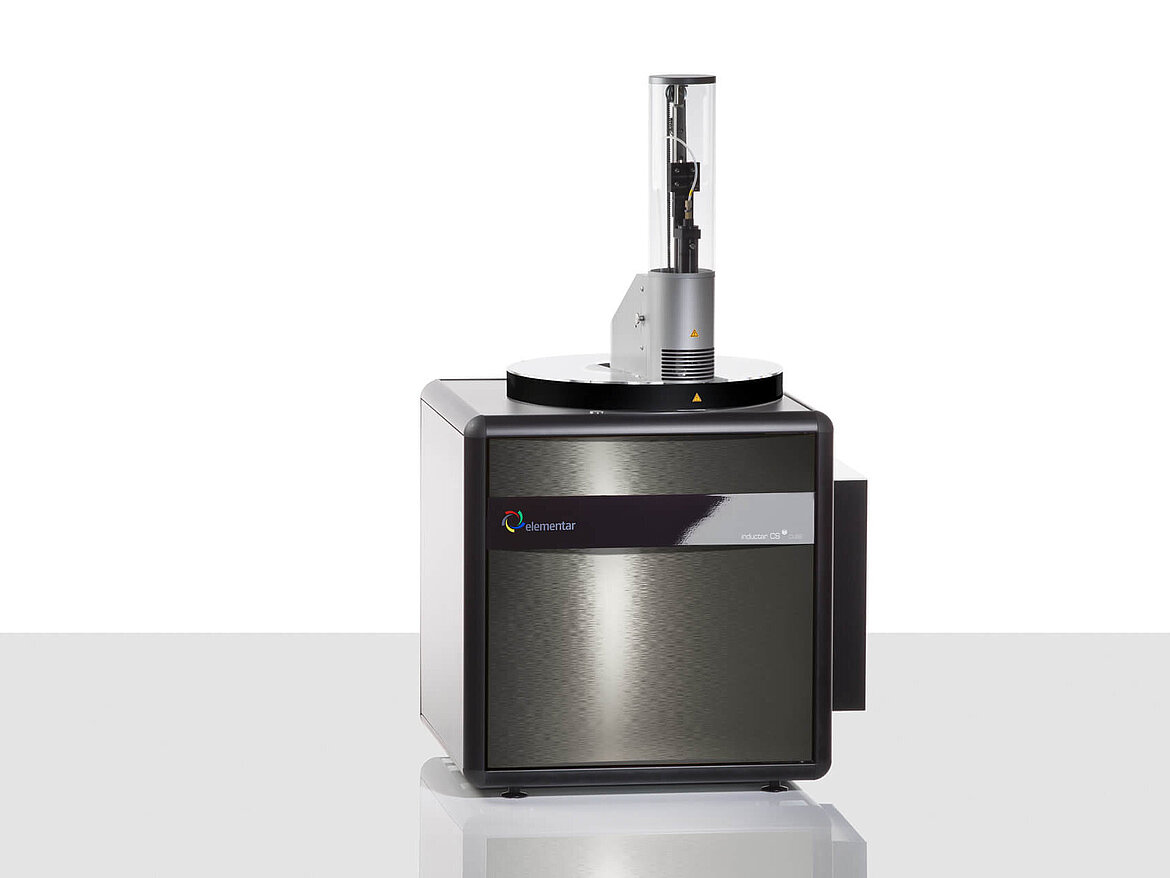

The carbon content in steel and other metals can be determined using elemental analysis or optical emission spectrometry (OES). Elemental analysis with the inductar® CS cube is ideal for the high-precision determination of carbon and sulfur in metals and other inorganic materials. Optical emission spectrometry, on the other hand, is ideal for determining the mass fraction or identifying metals and their alloys. With the ferro.lyte® mobile spark spectrometer, you can use positive material identification (PMI) on site at any time to ensure that the material you are using meets the required specifications.

Analyzers for the determination of carbon in metals

Further information about the analysis of the carbon content in steel

You want to analyze the chemical composition of steel to ensure your materials meet the required specifications? Contact us, our team will find the best solution for your application.

If you would like to receive our newsletter, by clicking on the “Submit” button you consent to receiving personalized newsletters by email from Elementar India Pvt Ltd and its group companies, as well as to the evaluation of my user behavior in this regard and – if available – the merging of this data with my data in our customer database.

In order to receive newsletters from our group companies, it is necessary to transmit the above-mentioned data to them. The data transfer to these recipients is legitimized by your consent, which you give by clicking on the “Submit” button.

The newsletter can be canceled at any time with effect for the future as well as my consent to the transfer to our group companies can be revoked at any time. A revocation does not affect the legality of the processing carried out on the basis of the consent until the revocation. For more information, please refer to our privacy policy.