Revolutionize your mobile metal analysis - with the intuitive spark spectrometer ferro.lyte®.

High mobility: Measure anywhere at any time

Measure exactly where your material is located. Compact design, low weight and the sophisticated all-in-one concept give you maximum flexibility in everyday measuring.

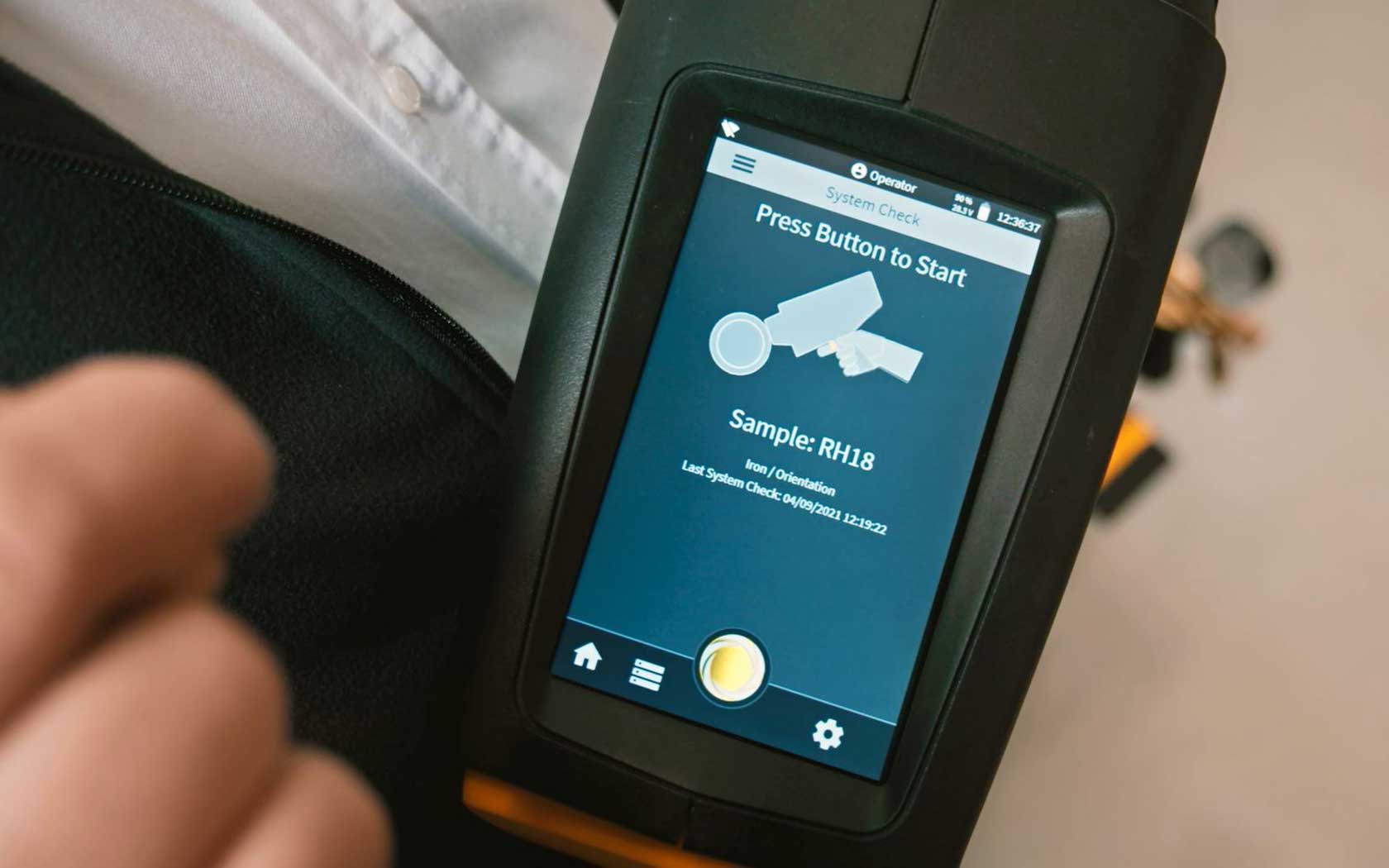

Intuitive operation: Analyses easier than ever

The intuitive lyticOS® software guides you through the measurement process with step-by-step workflows. This way, the entire measurement as well as the reporting can be controlled directly via the display of the handheld probe.

Precise metal analysis: results in laboratory quality

Mobile metal analysis more accurate than ever. Even light elements such as nitrogen in duplex stainless steel are analyzed in laboratory quality thanks to the CONLYTE® technology (filled as a patent).

Reliable results: Analyses and reports at the push of a button

Analyze and identify metal alloys reliably with ferro.lyte®. Results are available on the instrument at any time and can be conveniently backed up via cloud.

Easy handling

Whether in the warehouse, in production, or for outdoor use - use the lightweight ferro.lyte® to test metals even in hard-to-reach places. Thanks to the all-in-one concept, you can reach measuring points more easily than ever. Perform measurements quickly and conveniently with the intuitive lyticOS® software.

Laboratory-quality analyses

Analyze and identify metallic materials more precisely than ever before. ferro.lyte® also analyzes light elements such as nitrogen, sulfur and carbon with high accuracy - thanks to the CONLYTE® technology (filled as patent). Even alloying elements in the sub ppm range can be reliably detected.

Loss of efficiency in quality assurance? You should avoid these four pitfalls!

DOWNLOAD YOUR COPY

Fill in the form to receive your download link per e-mail.

Your contractual consideration for the free provision of the download is the subscription to our personalized newsletter. By clicking on the “download now” button, you therefore declare your acceptance of the receipt of personalized newsletters by e-mail by Elementar Americas, Inc. and its group companies as well as the evaluation of your user behavior in this regard and - if available - the merging of this data with your data in our customer database.

In order to receive newsletters from our group companies it is necessary to transfer your above-mentioned personal data to these companies. The data transfer is contractually required.

You are aware that the subscription to our personalized newsletter represents the contractual consideration that you provide for the free provision of the download. You can unsubscribe from the newsletter at any time with effect for the future. You can object to the future use of your data for advertising purposes at any time. For further information, please refer to our privacy policy.

Laboratory quality to go. Smart and powerful: the most compact mobile OES in detail.

Goes along all ways.

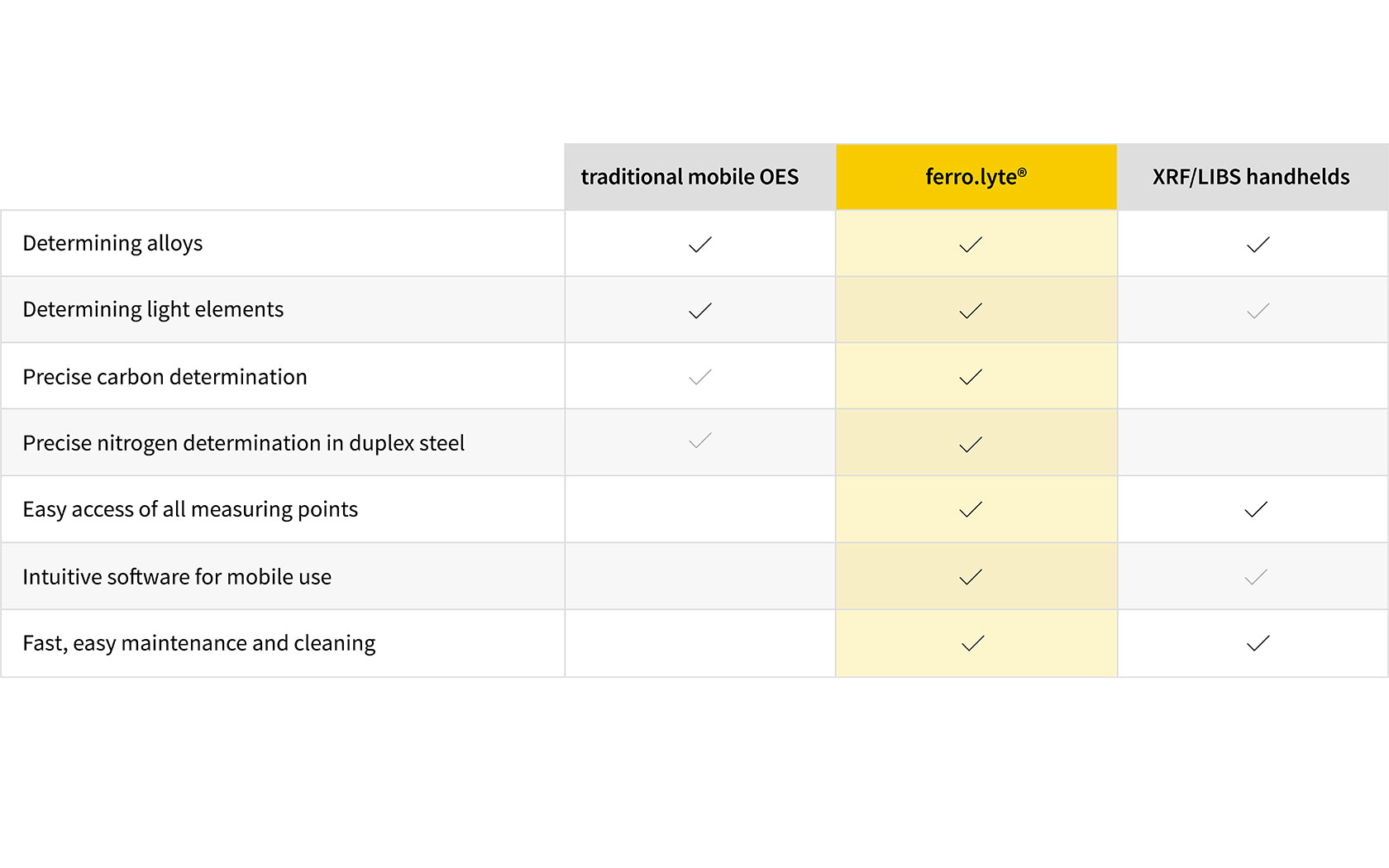

Stands up to any comparison.

The mobile OES in expert check

Mobile metal analysis can be performed by anyone - with ferro.lyte®. Our expert Hans Dominick shows you the main features and advantages at a glance.

Ease of use combined with precise measuring results is essential for the user of mobile metal analyses. This is what we measured ourselves against when designing ferro.lyte®. The result is an intuitive OES that anyone can use to quickly perform reliable measurements after a brief introduction. See for yourself in a personal live demo.

Hans Dominick (Product Manager Inorganic, Elementar Analysensysteme GmbH)

ferro.lyte® is at home in these industries among others

The quality requirements for workpieces are particularly high in mechanical engineering. Just like the efficiency pressure. What counts is timely and accurate metal identification that does not delay industrial processes. The analysis directly in the manufacturing process makes rapid further processing of bar stock, blanks, or semi-finished products made of metallic materials possible. The intuitive operation guarantees reliable metal analyses after a short instruction.

The materials of pipes, pipelines, or tanks in refineries and on oil rigs are exposed to high stresses due to temperature fluctuations, aggressive raw materials and chemical processes. Off- as well as on-shore also have to withstand seawater. Therefore, stringent specifications apply to metallic materials used. Duplex steels with defined nitrogen contents are mainly used. ferro.lyte® combines precise nitrogen determination with the greatest possible mobility in use.

Depending on the intended use, a wide range of metal alloys are used for tank and plant construction. Proof of correctly installed materials is therefore an important step in quality assurance. Welded structures are often used, and the composition of the steel plays a special role. The suitability for welding can be determined by means of the carbon equivalent. Using ferro.lyte®, material identification can be performed quickly and easily directly in the manufacturing process on site.

Why ferro.lyte®? Find all the details here.

Loss of efficiency in quality assurance? You should avoid these four pitfalls!

Do you know the four efficiency killers in metal analysis? In our whitepaper you will learn how to avoid them in your quality assurance and how to use them to your advantage.

Time-eater metal analysis? Discover the five key factors for more efficiency.

Learn how ferro.lyte® can help you increase mobility in your metal analysis, maximize safety, simplify processes, improve detection limits, facilitate data management, and thus optimize the efficiency of your on-site quality control.

Correct batch sorting? Learn how to check metals precisely.

Always keep an eye on your batches: With ferro.lyte®, you can reliably trace metals at any time during processing based on their trace element content. Learn how: Download our whitepaper now.

Determine and identify titanium materials? Learn more about our special titanium calibration.

Contact us for more information

You need more information? We will be happy to answer your questions about the ferro.lyte® mobile spark spectrometer and metal analysis. Let us know what interests you.

If you would like to receive our newsletter, by clicking on the “Submit” button you consent to receiving personalized newsletters by email from Elementar Americas, Inc. and its group companies, as well as to the evaluation of my user behavior in this regard and – if available – the merging of this data with my data in our customer database.

In order to receive newsletters from our group companies, it is necessary to transmit the above-mentioned data to them. The data transfer to these recipients is legitimized by your consent, which you give by clicking on the “Submit” button.

The newsletter can be canceled at any time with effect for the future as well as my consent to the transfer to our group companies can be revoked at any time. A revocation does not affect the legality of the processing carried out on the basis of the consent until the revocation. For more information, please refer to our privacy policy.