Taking oxygen analysis to the next level

At Elementar we are constantly driven to enhance the performance and reliability of our elemental analyzers. Based on user feedback, we have improved 4 key aspects of the rapid OXY cube®, which are detailed below.

5 mm Manual pressing tool = Solid samples fall reliably into the narrow ash crucible

This new pressing tool makes sure that your solid samples have the right size to fall into the rapid OXY cube’s narrow ash crucible. The handling is straightforward. A wrapped sample is first dropped into the inner cylinder of the manual pressing tool. Upon insertion of a rod, the sample is pressed into a shape, which will easily fall all the way into the narrow ash crucible.

Manual drilling tool = Easy removal of deposits formed in the pyrolysis tube by oil analysis

When analyzing light oils and solvents, soot deposits will start building up at about 12-15 cm depth inside the pyrolysis tube. These deposits need to be removed every 300 samples, which can easily be accomplished with the help of this new manual drilling tool. Additionally, we recommend lowering the pyrolysis temperature to 1,200 °C, since this creates softer deposits, which are more easily removed. For these types of samples, it can also be advantageous to remove the ash crucible and fill the upper part of the pyrolysis tube with graphite felts.

Survey about oxygen analysis

Participate in a short (<10 min) survey about oxygen analysis and receive one manual pressing tool or one manual drilling tool per rapid OXY cube. Additionally, the 5 participants who offer the most insight into their oxygen analysis, receive one “improved leak detection”-kit per rapid OXY cube.

Improved leak detection kit = Vastly better protection for your glassy carbon tube

For maximum longevity of your glassy carbon tube, we have improved the monitoring of the purging gas flow between the glassy carbon tube and the ceramic tube. This means that you are immediately alerted to a leaky ceramic tube and can replace it before damage is being caused to your glassy carbon tube. The “improved leak detection”-kit includes hardware parts as well as a software update, which reflects the modified functional scheme.

Improved IR detection = 3.5 min analysis time, highly reduced He consumption, lower system blank

Due to a 10-fold higher sensitivity, the IR detector has always been superior to the TCD. Now, IR detection is becoming even more powerful with the introduction of a new analysis mode, during which CO and other pyrolysis gases travel directly to the IR. This is possible because the IR detector only reacts to CO. The analysis time is significantly decreased from 15 min to 3.5 min, which in turn lowers the overall He consumption by up to 2.6 l per analysis. Additionally, the system blank is lowered by a factor of 3.

To unlock this new analysis mode, called O-direct mode, you can request a software update. If your rapid OXY cube is currently only equipped with a TCD, you have the option to install an IR detector at any point in time. A prerequisite for the O-direct mode is the installation of the “improved leak detection”-kit.

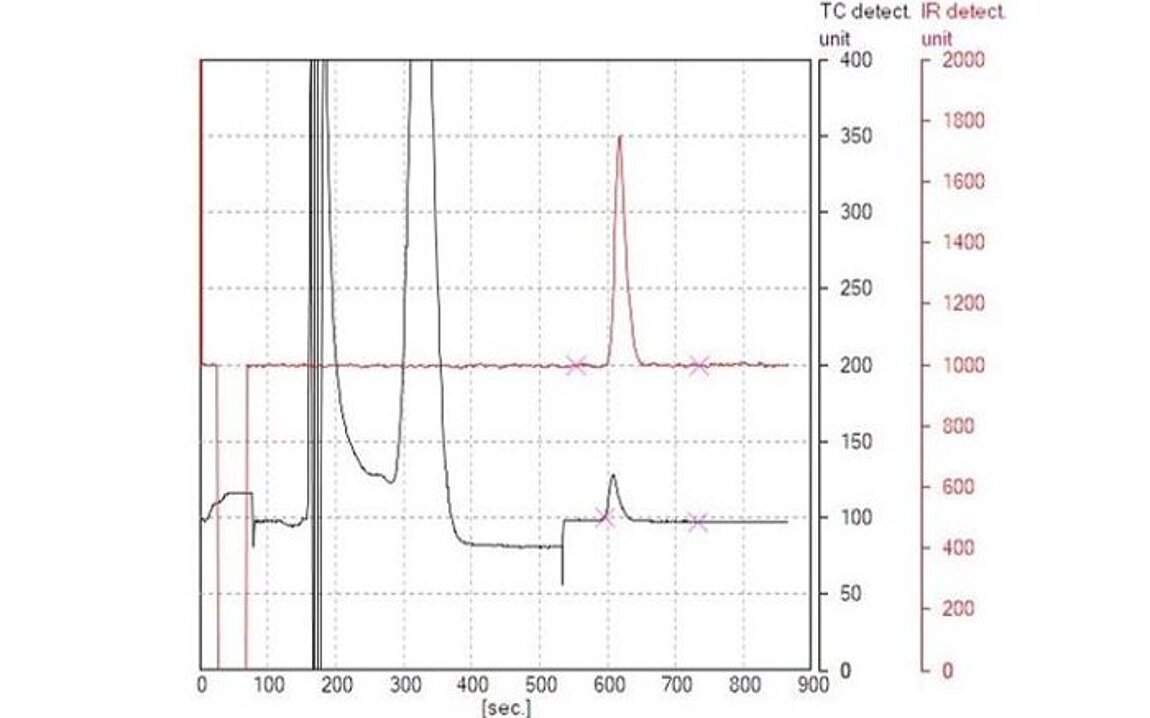

Standard mode:

IR detector has 10 x higher sensitivity than TCD and is unaffected by undesirable pyrolysis byproducts

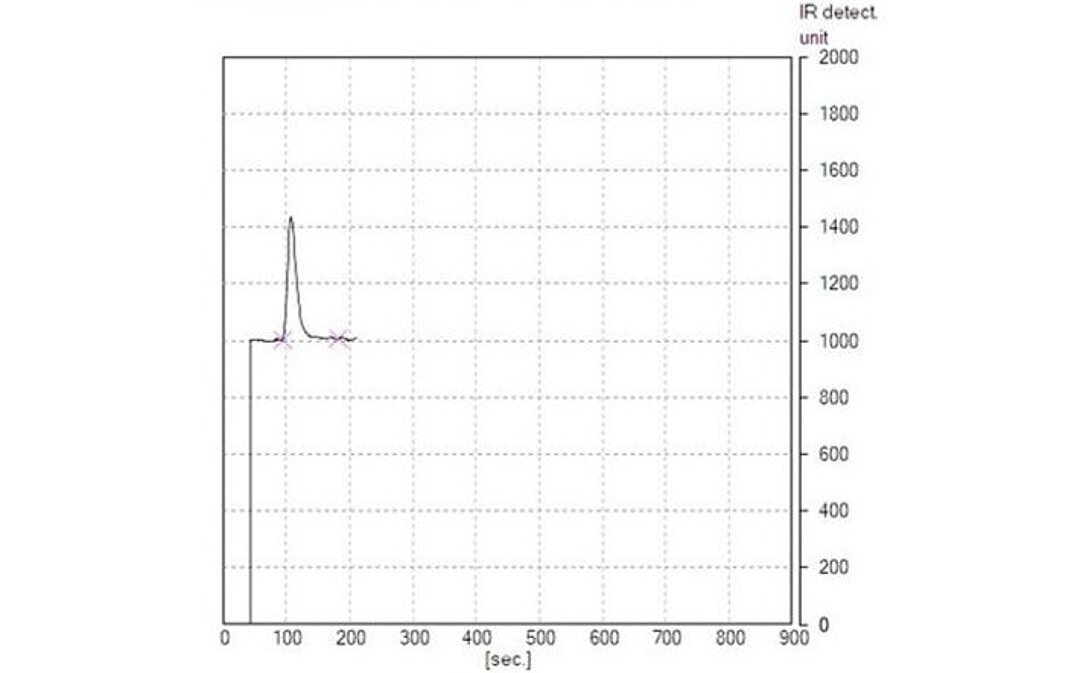

O-direct mode:

Analysis time of 3.5 min instead of 15 min (= 2.6 L He savings); IR peak area is smaller than in standard mode because the system blank is 3 x lower

Interested in this powerful new analysis mode?

Read our technical note that details a standard addition experiment in the low ppm oxygen range.